Diamond saw blades can incorporate various cooling mechanisms to manage the heat generated during the cutting process. Efficient heat dissipation is crucial for maintaining the blade's performance, preventing overheating, and extending its lifespan. Here are common cooling mechanisms used in diamond saw blades:

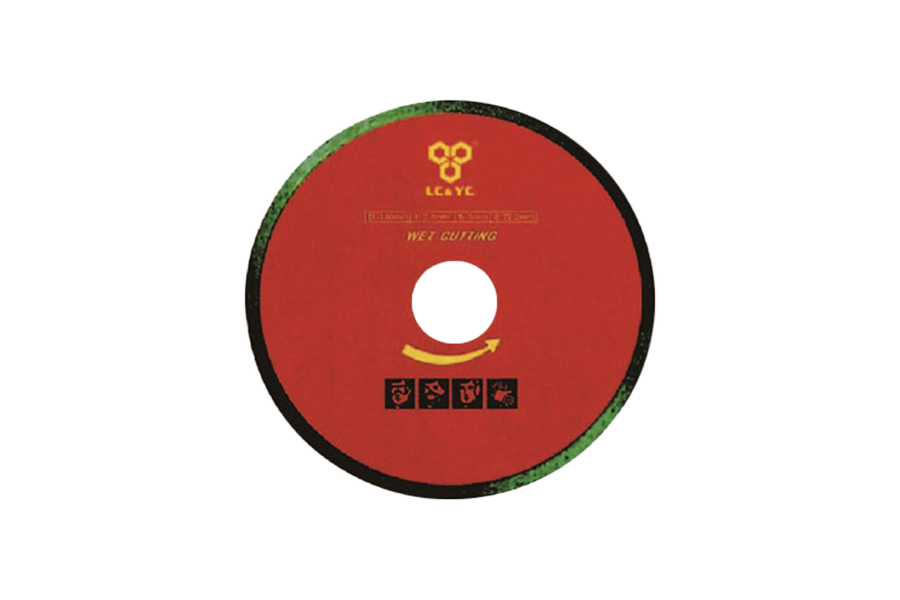

Water Cooling:

Many diamond saw blades are designed for wet cutting, where water is used as a cooling agent. Water is continuously supplied to the cutting area, reducing friction and dissipating heat. Wet cutting not only cools the blade but also helps in dust suppression and improving cutting efficiency.

Coolant Channels:

Some diamond saw blades have built-in channels or holes that allow for the circulation of coolant, typically water or water-based solutions. These channels help direct the coolant to the cutting area, providing effective cooling during the cutting process.

Laser-Cut Cooling Holes:

Some blades feature laser-cut cooling holes strategically placed along the circumference of the blade. These holes allow for better air circulation and heat dissipation during operation.

Turbo Segments:

Turbo segments on a diamond saw blade have a serrated or fluted design that enhances airflow around the cutting edge. This design helps in dissipating heat more effectively, reducing the risk of overheating and prolonging the blade's life.

Ventilation Design:

The overall design of the blade may incorporate ventilation features to facilitate air circulation around the cutting edge. This helps in dissipating heat and preventing the blade from becoming excessively hot during extended use.

Segmented Blade Design:

Segmented diamond blades, with gaps or spaces between the segments, allow for better airflow and cooling during cutting. This design helps prevent the buildup of heat and reduces the chances of the blade warping or losing its cutting efficiency.

Heat-Resistant Materials:

The choice of materials in the blade's construction can contribute to heat resistance. Some blades use materials that withstand higher temperatures, reducing the impact of heat on the blade's overall performance.

Anti-Stick Coatings:

Some diamond blades feature anti-stick coatings that help prevent material buildup on the blade's surface. This can contribute to smoother cutting and reduce friction, consequently managing heat more effectively.

High-Quality Bonds:

The bond material that holds the diamond particles in place plays a role in heat management. High-quality bonds are designed to withstand the heat generated during cutting without losing their integrity.

Variable Tooth Design:

Blades with a variable tooth design may incorporate gullets or recessed areas between teeth. These features enhance chip evacuation and prevent heat buildup by allowing the cutting debris to be expelled more efficiently.

Continuous Rim Blades:

Continuous rim diamond blades, which have a smooth and continuous cutting edge, provide more surface area for heat dissipation. They are commonly used for materials like glass or tiles.

Reduced Friction Coatings:

Some diamond blades are coated with materials that reduce friction during cutting, minimizing heat generation. These coatings can contribute to smoother cutting and improved heat management.

The choice of cooling mechanism depends on the specific application and the materials being cut. Wet cutting with water cooling is particularly effective for materials like concrete and stone.

English

English

中文简体

中文简体

Español

Español

عربى

عربى