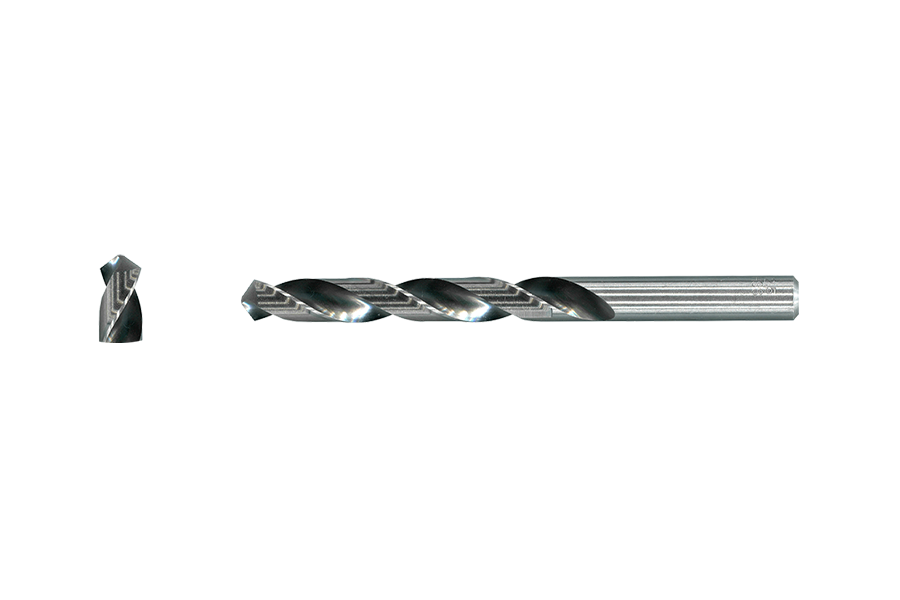

Coatings on High-Speed Steel (HSS) drill bits play a crucial role in improving their performance and durability. These coatings are designed to provide additional properties that enhance the tool's ability to cut through materials efficiently and resist wear and heat. Here are ways in which coatings contribute to the performance and durability of HSS drill bits:

Increased Hardness:

Coatings like TiN, TiCN, TiAlN, ZrN, and DLC are applied to increase the hardness of the drill bit's surface.

Higher hardness enhances the tool's ability to withstand abrasion and deformation during drilling, especially when working with hard materials.

Wear Resistance:

Coatings act as a protective layer, reducing wear on the cutting edges of the drill bit.

This wear resistance is crucial for prolonging tool life, especially in applications where abrasion and friction are significant factors.

Reduced Friction:

Coatings, such as TiN and DLC, reduce friction between the drill bit and the workpiece.

Lower friction results in less heat generation during drilling, reducing the risk of tool overheating and extending the tool's lifespan.

Enhanced Lubricity:

Some coatings provide improved lubricity, allowing the drill bit to move more smoothly through the material.

Enhanced lubricity contributes to reduced chip adhesion and improved chip evacuation, promoting better drilling performance.

High-Temperature Resistance:

Coatings like TiAlN and ZrN offer resistance to high temperatures generated during high-speed drilling.

High-temperature resistance is critical for maintaining the integrity of the cutting edges and preventing tool failure in demanding applications.

Corrosion Resistance:

Coatings, including black oxide and DLC, can provide corrosion resistance, protecting the drill bit from rust and other forms of corrosion.

Corrosion resistance is particularly important for extending the tool's life and maintaining cutting performance over time.

Improved Chip Flow:

Coatings with low friction properties contribute to improved chip flow and evacuation during the drilling process.

Efficient chip removal prevents chip congestion, reduces heat buildup, and prevents chip-induced damage to the cutting edges.

Extended Tool Life:

The combined effects of increased hardness, wear resistance, reduced friction, and improved lubricity contribute to an extended tool life.

Coated drill bits are less prone to premature wear and are better equipped to handle challenging materials.

Versatility Across Materials:

Different coatings may be optimized for specific materials or applications. For example, TiAlN coatings are often suitable for high-speed machining and hard materials.

Coated drill bits exhibit versatility, allowing them to perform well across a range of materials, from soft to hard.

English

English

中文简体

中文简体

Español

Español

عربى

عربى