The geometry of the tip of a masonry drill bit has a significant impact on its drilling performance, especially when working with hard materials such as concrete, brick, or stone. Here are key aspects of tip geometry and their effects on drilling performance:

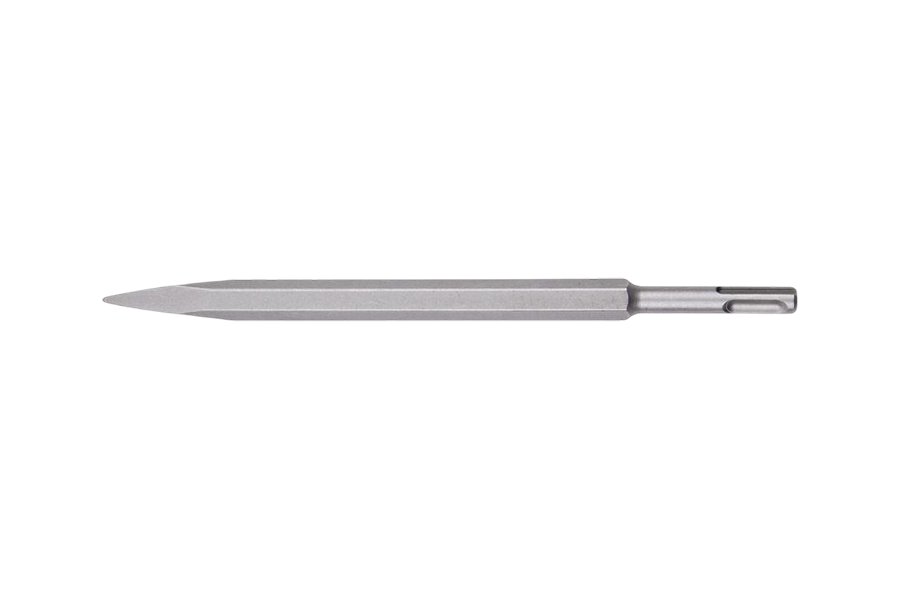

Tip Shape:

Conical Tips: Conical tips are common for masonry drill bits. The pointed shape allows for easier penetration into hard materials. The angle of the cone affects the aggressiveness of the bit, with steeper angles providing more efficient cutting but potentially generating more heat.

Flat Tips: Flat tips, also known as spade tips, offer a larger surface area for initial contact with the material. They are suitable for softer masonry materials.

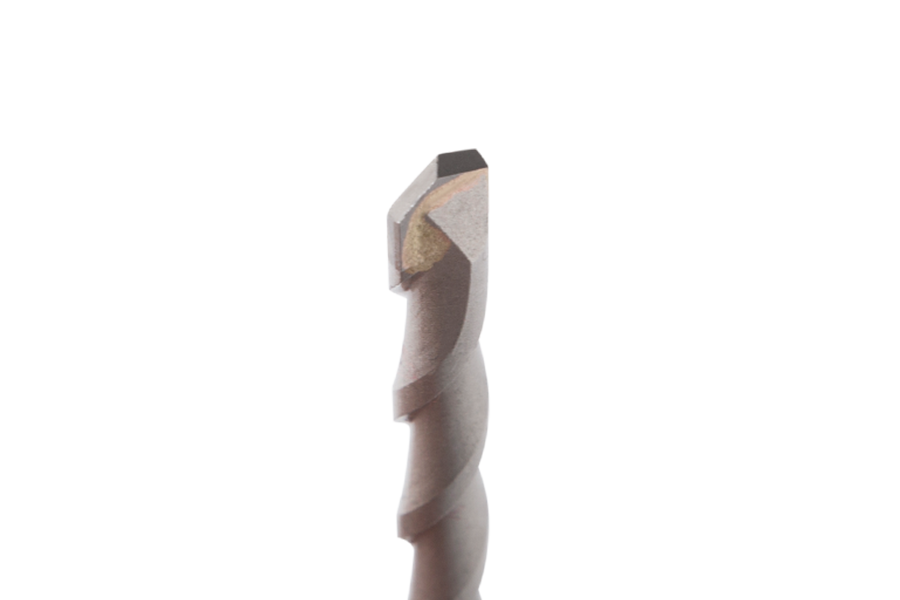

Material Composition:

Carbide Tips: Many masonry drill bits have tips made of carbide. Carbide is a hard and durable material that enhances the drill bit's ability to withstand the abrasive nature of hard materials. Tungsten carbide is a common choice for masonry drill bit tips.

Diamond Tips: In some high-end masonry drill bits, the tips may be embedded or coated with diamonds. Diamond tips offer exceptional hardness and are effective for drilling through extremely hard materials.

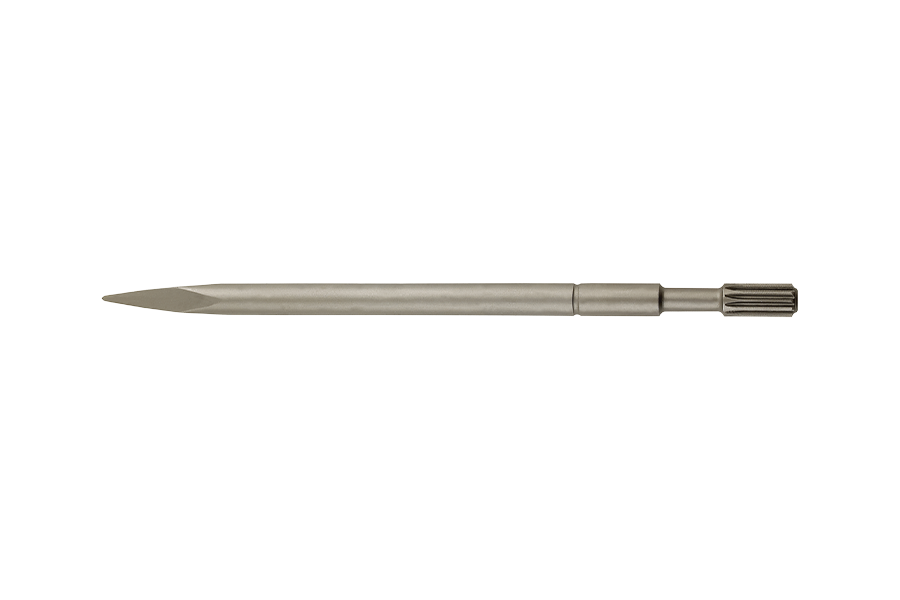

Flute Design:

Helical Flutes: The design of the flutes, or channels, on the drill bit plays a role in chip evacuation. Helical flutes help remove debris efficiently, reducing heat buildup and preventing the bit from getting clogged during drilling.

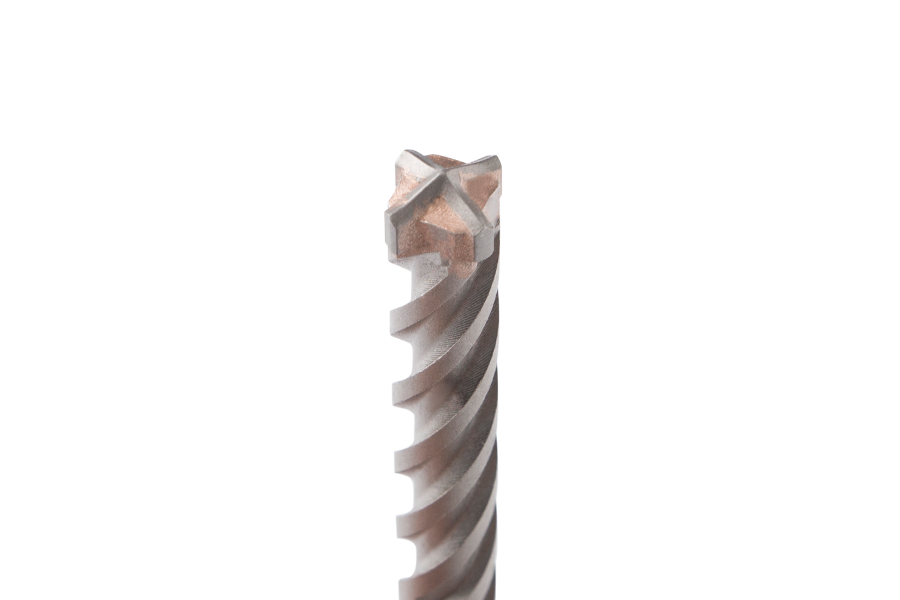

Tip Configuration:

Single Tip vs. Multiple Tips: Some masonry drill bits have a single tip, while others may have multiple tips arranged in various patterns. Multiple tips can distribute the drilling load more evenly, reducing wear on individual tips and improving overall performance.

Chisel and Crosshead Tips:

Chisel Tips: Chisel tips are flat and suitable for applications that require more precise drilling. They are often used for creating holes where anchor bolts will be placed.

Crosshead Tips: Crosshead tips have a cross-shaped design and are more aggressive. They are effective for faster drilling in harder materials.

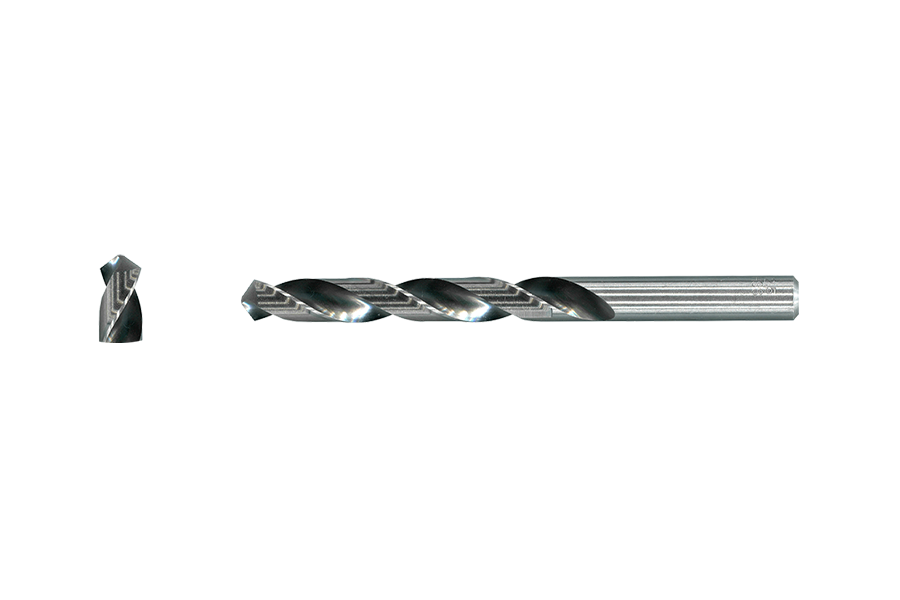

Point Angle:

The point angle of the drill bit refers to the angle formed by the cutting edges at the tip. A sharper point angle (smaller angle) tends to be more aggressive, providing faster cutting but potentially generating more heat. A larger point angle may be more suitable for softer materials.

Flute Length:

The length of the flutes affects the drilling depth and the efficiency of chip removal. Longer flutes are often used for deeper drilling, while shorter flutes may be more stable and less prone to wandering.

Helix Angle:

The helix angle refers to the angle of the flutes relative to the axis of the drill bit. A higher helix angle can result in more aggressive cutting action, while a lower helix angle may provide more stability.

The optimal tip geometry depends on the specific characteristics of the material being drilled, the desired drilling speed, and the type of drill being used. Different tip geometries are designed to address various challenges, such as minimizing heat buildup, preventing bit wander, and ensuring efficient chip removal. When selecting a masonry drill bit, considering the hardness of the material and the specific application requirements is crucial to achieving optimal drilling performance.

English

English

中文简体

中文简体

Español

Español

عربى

عربى