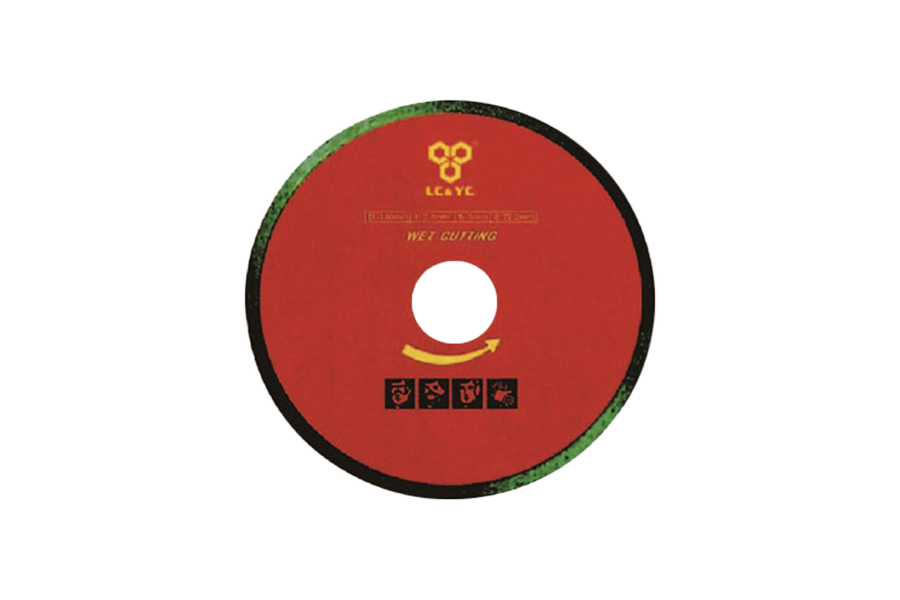

The choice of diamond saw blade depends on several factors, each of which influences the blade's performance, efficiency, and suitability for a specific cutting application. Some key factors to consider when selecting a diamond saw blade include:

Material to be Cut: The type of material being cut is one of the most critical factors in choosing a diamond saw blade. Different blades are designed for cutting materials such as concrete, asphalt, stone, ceramic, glass, metal, or composite materials. Each material has unique properties that require specific blade characteristics, such as diamond grit size, bond type, and segment design.

Material Hardness: The hardness of the material being cut influences the selection of the diamond saw blade. Harder materials require diamond blades with a higher diamond concentration and a softer bond to ensure efficient cutting and extended blade life. Conversely, softer materials may require blades with a lower diamond concentration and a harder bond to prevent excessive wear and maintain cutting precision.

Cutting Depth and Thickness: The desired cutting depth and thickness of the material also play a role in blade selection. Diamond saw blades come in various sizes and thicknesses to accommodate different cutting requirements. Blades with deeper segments or larger diameters are suitable for cutting thicker materials or achieving greater cutting depths.

Wet or Dry Cutting: The cutting environment, whether wet or dry, influences the choice of diamond saw blade. Wet cutting is preferred for reducing heat buildup, minimizing dust, and extending blade life, especially when cutting hard materials or large volumes. Dry cutting may be suitable for smaller jobs or where water access is limited, but it can result in faster blade wear and reduced cutting efficiency.

Machine Compatibility: The type and specifications of the cutting machine or saw determine the compatibility of the diamond saw blade. Blades must be selected to match the machine's arbor size, RPM rating, and horsepower requirements to ensure safe and effective operation.

Cutting Speed and Efficiency: The desired cutting speed and efficiency influence the choice of diamond saw blade. Blades with higher diamond concentrations and optimized segment designs offer faster cutting speeds and improved efficiency, reducing cutting time and increasing productivity.

Surface Finish Requirements: The desired surface finish of the cut material also affects blade selection. Blades with different segment designs and bond types produce varying surface finishes, ranging from smooth and polished to rough and textured. The application's surface finish requirements, such as for architectural or decorative purposes, dictate the choice of blade.

Budget and Cost Considerations: Budget constraints and cost considerations may impact blade selection. Higher-quality diamond saw blades with advanced features and longer lifespans may have a higher upfront cost but offer better value in terms of performance, durability, and overall cutting efficiency, leading to cost savings in the long run.

English

English

中文简体

中文简体

Español

Español

عربى

عربى