Diamond saw blades achieve cutting performance through a combination of factors and design features that optimize their cutting efficiency, precision, and durability. Here are the key measures taken to enhance the wear resistance and longevity of diamond saw blades:

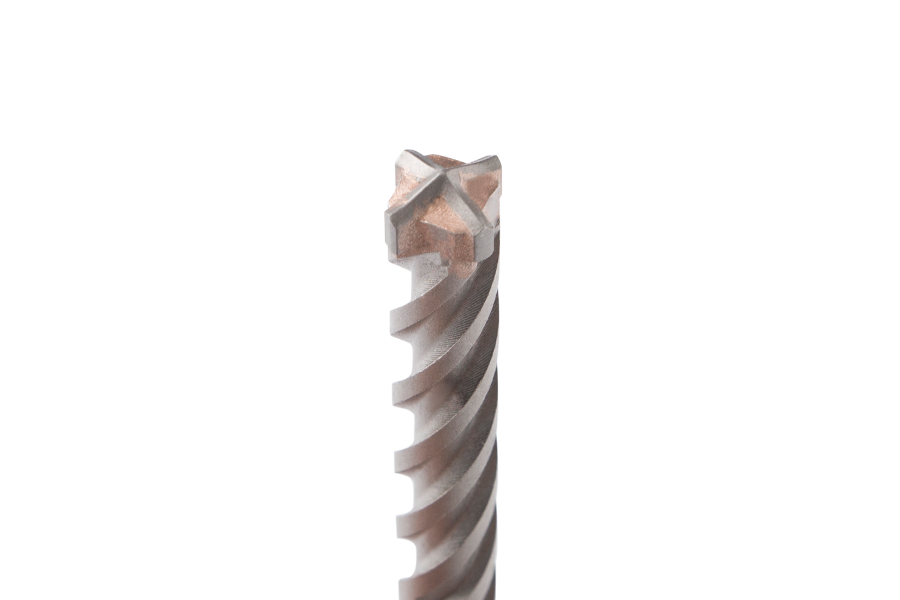

Diamond Grit Quality: High-quality diamond grit is crucial for achieving efficient cutting performance and extended blade life. Manufacturers carefully select diamond crystals with uniform shape, size, and strength to ensure consistent cutting effectiveness and resistance to wear.

Diamond Concentration: The concentration of diamond grit in the bond matrix directly impacts the cutting performance and longevity of the blade. Higher diamond concentrations result in more aggressive cutting action and longer blade life, as there are more cutting points available to wear down gradually.

Bond Matrix Composition: The bond matrix material that holds the diamond grit in place plays a critical role in blade performance. Manufacturers formulate bond matrices with varying hardness, toughness, and thermal stability to optimize cutting efficiency, wear resistance, and blade longevity under different cutting conditions.

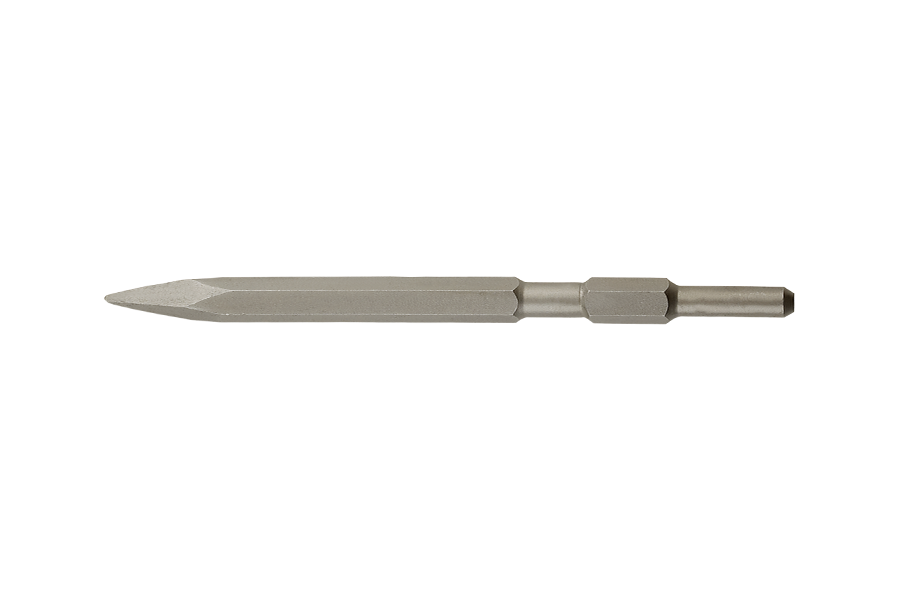

Segment Design: The design and configuration of the diamond segments on the blade rim significantly influence cutting performance and durability. Segments are engineered with specific shapes, sizes, and arrangements to ensure efficient debris removal, cooling, and diamond exposure during cutting. Segments with reinforced cores or added protection layers enhance durability and resistance to segment loss or damage.

Segment Width and Height: The width and height of diamond segments affect the blade's stability, cutting depth, and wear resistance. Wider and taller segments provide greater support and cutting depth, reducing segment flexing and minimizing wear on the bond matrix and diamond grit.

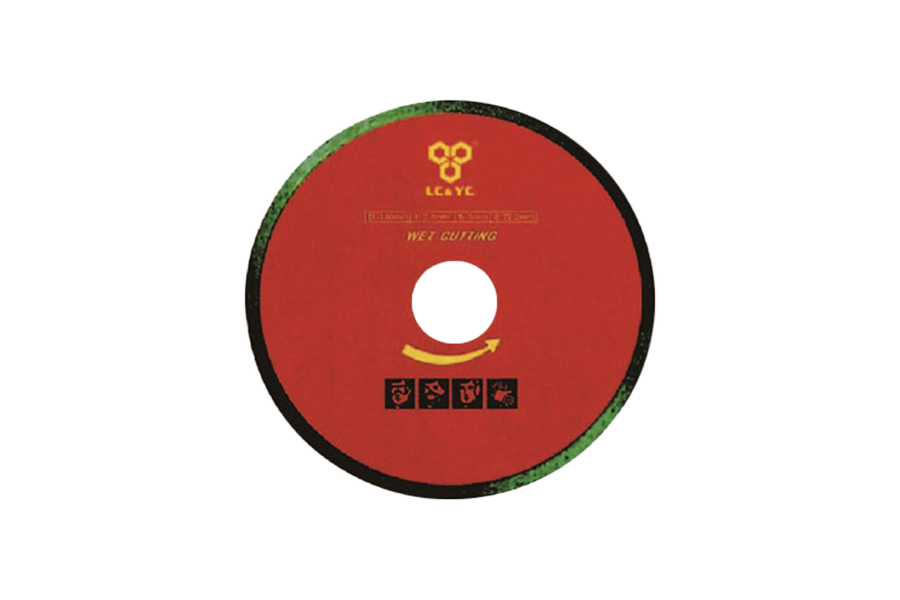

Cooling and Lubrication: Effective cooling and lubrication mechanisms are essential for reducing heat buildup and preventing premature wear of the blade. Water or coolant is commonly used during wet cutting operations to dissipate heat, flush away debris, and lubricate the cutting surface, resulting in cooler cutting temperatures and extended blade life.

Continuous Rim vs. Segmented Rim: Diamond saw blades are available in continuous rim and segmented rim designs, each suited for specific cutting applications. Continuous rim blades provide smoother cuts and are ideal for delicate materials, while segmented rim blades offer faster cutting speeds and better debris removal, enhancing wear resistance and longevity.

Proper Use and Maintenance: Following proper cutting techniques, such as using the appropriate cutting speed, feed rate, and pressure, helps minimize blade wear and prolong blade life. Additionally, regular inspection, cleaning, and maintenance of the blade, including sharpening or dressing worn segments, ensure optimal cutting performance and longevity over time.

English

English

中文简体

中文简体

Español

Español

عربى

عربى