Diamond saw blades achieve cutting performance through the combination of their design, materials, and cutting principles. Here's how they work:

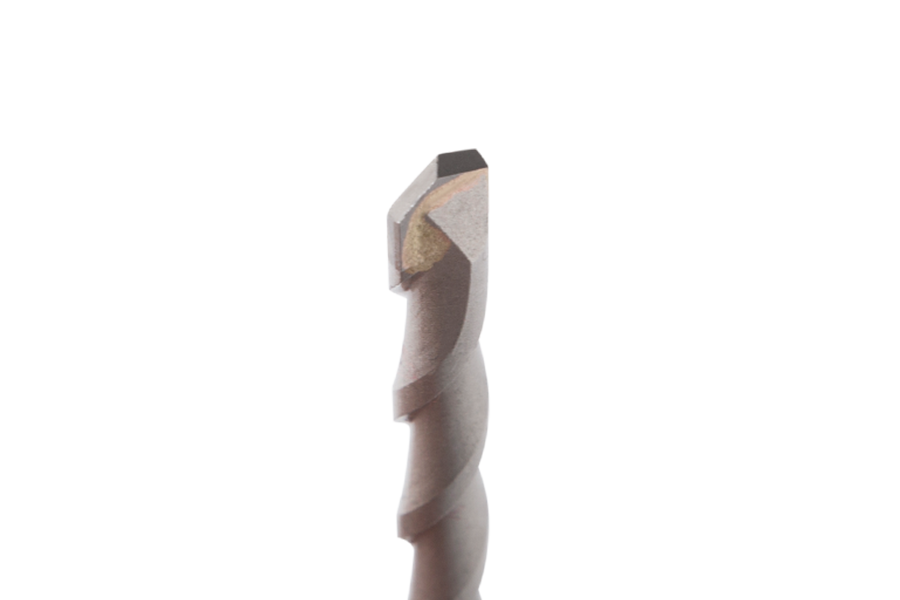

Diamond Grit: Diamond saw blades feature small diamond particles (grit) embedded in the cutting segments or rim of the blade. Diamond is one of the hardest known materials, making it highly effective for cutting a wide range of materials, including concrete, asphalt, stone, ceramic, and metal.

Bonding Matrix: The diamond grit is held in place by a bonding matrix, typically composed of metal powders (such as cobalt or bronze) mixed with a binder material. The bonding matrix acts as a support structure for the diamond particles, providing strength, durability, and resistance to heat and wear during cutting.

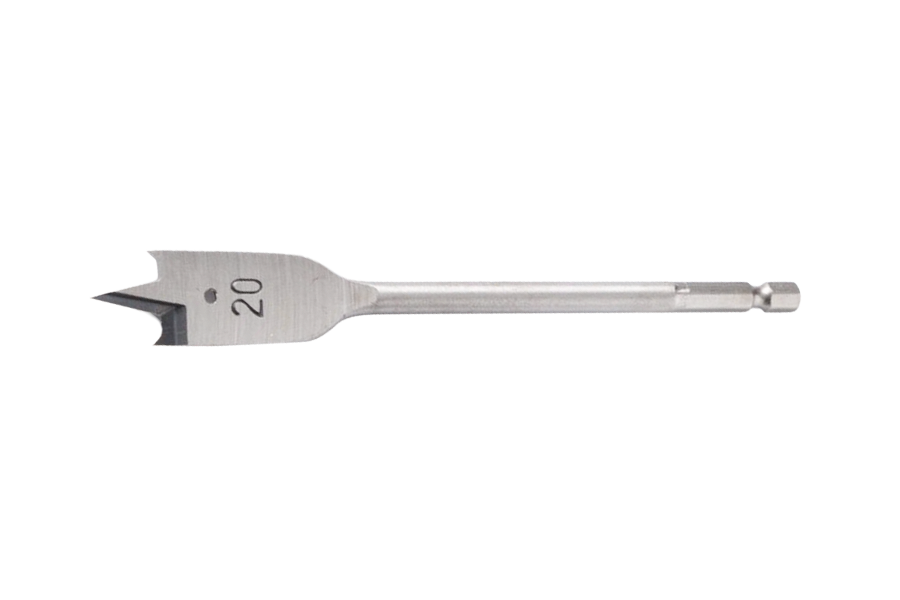

Segment Design: The cutting segments or rim of the diamond saw blade are designed with specific shapes and configurations tailored to the material being cut. Different segment designs, such as segmented, turbo, continuous, or segmented turbo, offer varying cutting characteristics and performance benefits.

Segment Composition: The composition of the cutting segments, including the size, concentration, and quality of diamond grit, directly influences cutting performance. Blades with higher diamond concentrations and finer diamond grit sizes offer superior cutting efficiency, precision, and longevity.

Cooling and Lubrication: During cutting, diamond saw blades generate heat and friction, which can cause damage to the blade and reduce cutting efficiency. Water or coolant is often used to cool and lubricate the blade, dissipating heat, flushing away debris, and prolonging blade life. Wet cutting is preferred for most applications due to its cooling and dust suppression benefits.

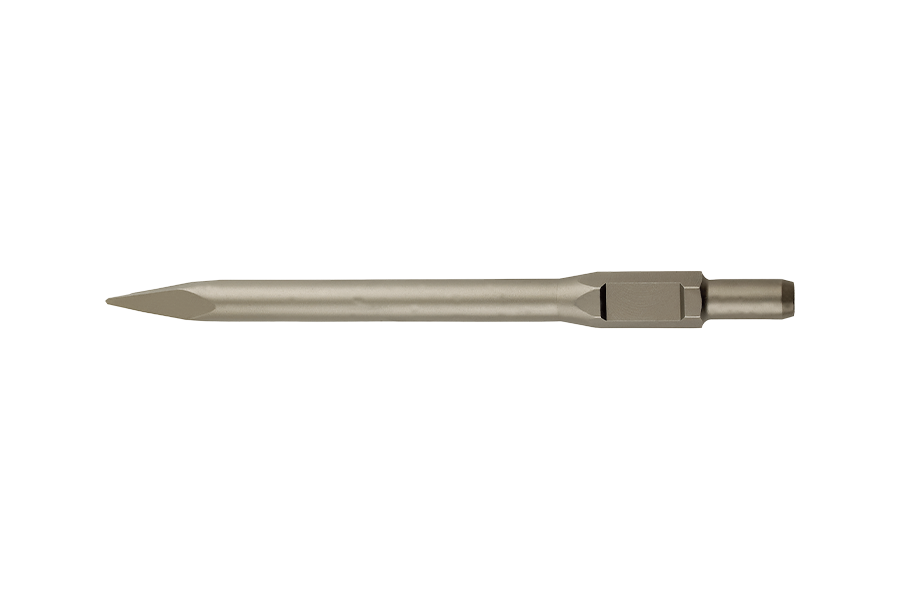

Cutting Speed and Feed Rate: The cutting speed (RPM) and feed rate (forward movement) of the saw blade also affect cutting performance. Optimal cutting parameters depend on factors such as material type, thickness, hardness, and machine specifications. Adjusting cutting speed and feed rate helps maximize cutting efficiency and blade lifespan while minimizing heat buildup and wear.

Operator Technique: Proper operator technique, including blade alignment, pressure, and cutting angle, is essential for achieving optimal cutting performance. Maintaining steady, consistent cutting motion and avoiding excessive force or lateral movement helps prevent blade deflection, binding, and premature wear.

Blade Maintenance: Regular blade maintenance, such as cleaning, sharpening, and periodic inspection for damage or wear, is crucial for maintaining cutting performance and prolonging blade life. Cleaning the blade after each use removes built-up debris and prevents clogging, while sharpening restores cutting effectiveness and extends blade lifespan.

By optimizing these factors in combination, diamond saw blades achieve cutting performance by efficiently harnessing the abrasive properties of diamond grit to cut through a wide range of materials with precision, speed, and durability.

English

English

中文简体

中文简体

Español

Español

عربى

عربى