1. Proper Tool Selection for the Job

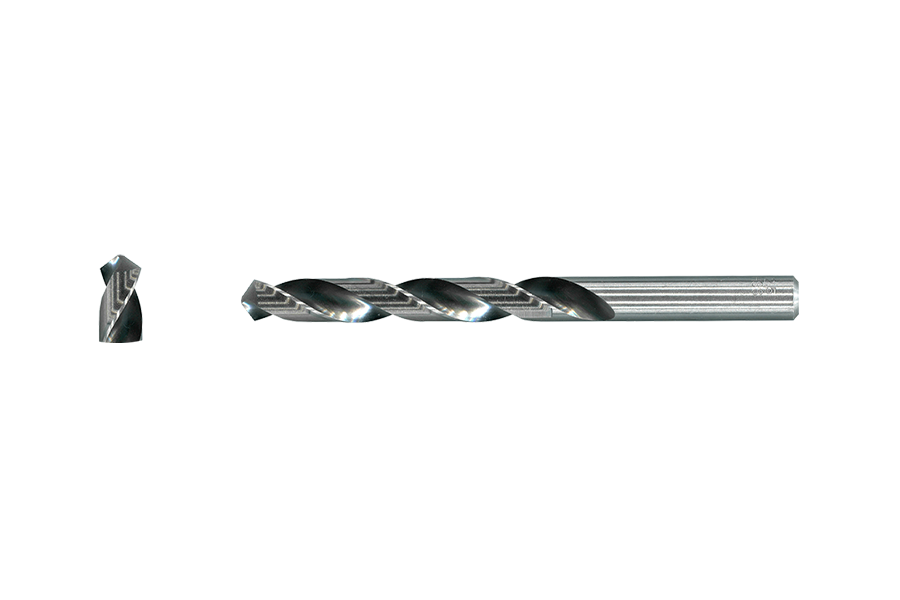

Using the right SDS Max drill bit for your specific project is the first step toward achieving optimal performance. Different materials require different bit specifications, and choosing a drill bit that’s not suited to the task can result in poor drilling efficiency or premature wear.

Hard Concrete: For tough materials like reinforced concrete, look for drill bits with a high-quality carbide tip and a robust design that can handle the additional strain. These bits are specifically engineered to withstand the impact required for heavy-duty work.

Masonry and Brick: For softer materials like masonry and brick, a standard carbide-tipped SDS Max drill bit should suffice. However, make sure to select a bit with a proper tip geometry to ensure smooth drilling with minimal effort.

2. Use the Right Drilling Technique

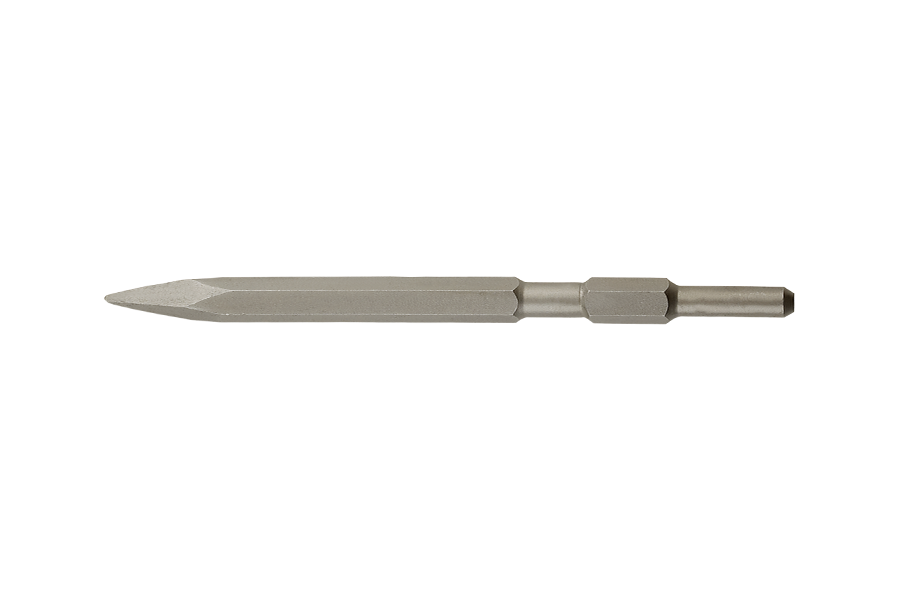

Maximizing the performance of your SDS Max drill bit also involves using the correct drilling techniques. Following the right procedure can reduce wear and tear on the bit while improving drilling efficiency.

Pre-Drill Small Holes: If you're tackling particularly tough materials, starting with a smaller diameter hole can help to break the surface before using a larger drill bit. This reduces the strain on the bit and ensures more precise drilling.

Steady Pressure: Applying consistent, moderate pressure on the drill will help the bit maintain its cutting efficiency. Avoid excessive force, as it can lead to overheating, premature dulling, and even breakage of the drill bit.

Avoid Overheating: When drilling into hard materials, overheating can lead to the degradation of the bit’s carbide tip. Take breaks between drilling sessions, especially when working with thick or dense materials, to allow the bit to cool down.

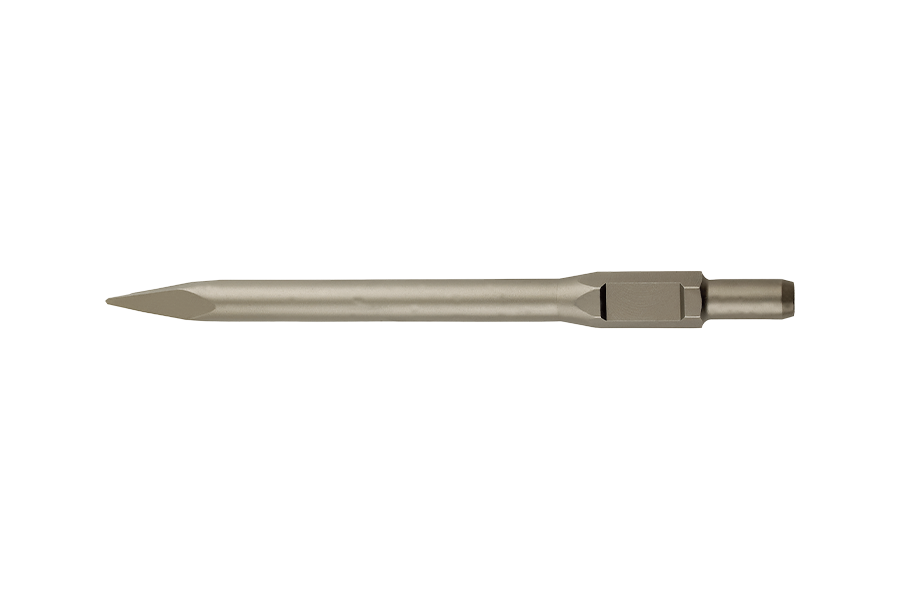

3. Regular Maintenance

Maintaining your SDS Max drill bits is key to preserving their performance and extending their lifespan. Regular cleaning and proper storage can make a significant difference.

Clean After Use: Concrete and masonry dust can quickly build up and affect the sharpness and effectiveness of your drill bit. After each use, clean the bit with a wire brush to remove any debris. This will help maintain the bit’s cutting edges and improve its performance during subsequent jobs.

Storage: Proper storage is also important for maintaining your SDS Max drill bit’s integrity. Store the bits in a dry, clean environment and ensure they are not subjected to impact or pressure that could damage the tips.

4. Ensure Compatibility with the Drill

To get the best performance from your SDS Max drill bit, make sure that it is compatible with the hammer drill or rotary hammer you are using. An incompatible drill could reduce the impact force, compromising drilling efficiency.

Check the Chuck: Before using an SDS Max drill bit, ensure your drill has an SDS Max chuck. SDS Max drill bits are designed to fit specific chucks, so make sure the tool is properly equipped to handle the bit.

Adjust the Hammer Function: Many rotary hammers allow you to adjust the hammer function, offering different levels of impact. For tougher materials, using the highest setting can maximize drilling efficiency.

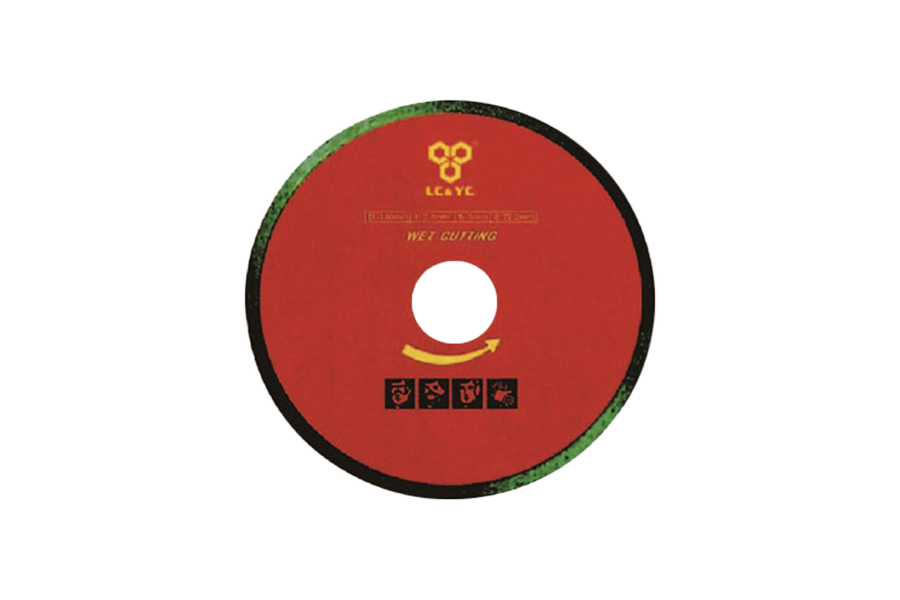

5. Sharpening and Replacement

Eventually, every drill bit will show signs of wear, especially after prolonged use. Regularly inspect your SDS Max drill bits for any signs of dulling or damage. If the tip begins to lose its sharpness, consider sharpening the bit or replacing it entirely.

Resharpening: Carbide-tipped SDS Max drill bits can be sharpened by a professional tool sharpening service. This can help to restore the tip's cutting efficiency, but only do this when the bit’s wear is moderate.

Replace When Necessary: If the bit has become severely worn or damaged, it’s time for a replacement. Continuing to use a worn-out bit can slow down your work and damage the material being drilled.

English

English

中文简体

中文简体

Español

Español

عربى

عربى