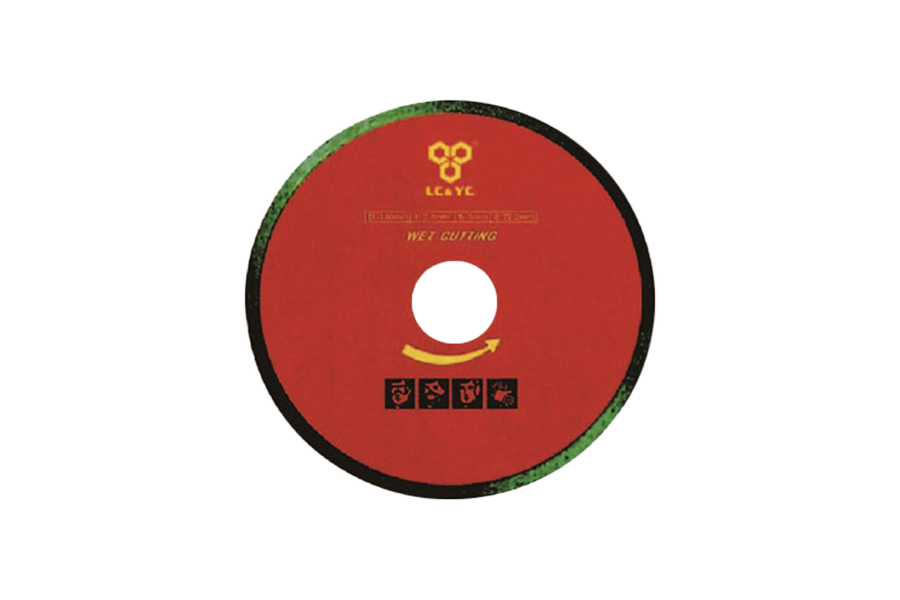

In the world of cutting tools, diamond saw blades have emerged as a pinnacle of innovation, combining strength, precision, and versatility. Initially developed for industrial applications, these blades have evolved to meet the needs of various sectors, including construction, manufacturing, and even artistic endeavors. The core of a diamond saw blade is its unique composition, featuring a metal bond matrix embedded with diamond particles. This distinctive structure not only enhances durability but also provides exceptional cutting performance.

One of the most significant advantages of diamond saw blades is their ability to cut through hard materials, such as concrete, granite, and ceramics. Traditional saw blades, often made from steel or carbide, struggle with these tough substances, leading to quicker wear and less efficient cuts. In contrast, diamond blades maintain their cutting edge longer, reducing the frequency of replacements and minimizing downtime on projects. This longevity translates into cost savings for contractors and manufacturers alike.

Moreover, the precision of diamond saw blades is unparalleled. The fine diamond particles allow for smoother cuts with minimal chipping, resulting in cleaner edges and less waste material. This precision is particularly beneficial in applications where aesthetics are important, such as in stone fabrication and tile installation. A well-executed cut can make a significant difference in the overall appearance of a finished product.

Environmental considerations are also increasingly influencing the design and use of diamond saw blades. Many manufacturers are focusing on creating blades that not only provide high performance but are also eco-friendly. This includes innovations in the bonding materials used, reducing harmful emissions during production and use. Furthermore, the longevity of diamond blades contributes to sustainability; by using fewer resources over time, they support a more responsible approach to construction and manufacturing.

The versatility of diamond saw blades cannot be overstated. Available in various sizes and configurations, they can be tailored for specific applications, from cutting large slabs of stone to precise slicing of delicate materials. This adaptability makes them essential tools across multiple industries. Whether a contractor is working on a large-scale construction site or a craftsman is engaged in fine art, the right diamond saw blade can make all the difference in achieving optimal results.

As technology continues to advance, we can expect further innovations in the design and performance of diamond saw blades. From improved bonding techniques to advancements in diamond grit sizes, the future holds exciting possibilities for enhancing cutting efficiency and precision. For manufacturers and users alike, staying abreast of these developments will be crucial in maintaining a competitive edge.

English

English

中文简体

中文简体

Español

Español

عربى

عربى