The evolution of construction tools has always been closely tied to technological advancements. Among these tools, SDS MAX chisels stand out as a testament to continuous innovation and engineering excellence. From their inception to modern-day applications, SDS MAX chisels have undergone significant transformations, shaping the way construction projects are executed worldwide.

Origin and Development

The story of SDS MAX chisels begins with the introduction of the SDS (Slotted Drive System) in the 1970s by Bosch, revolutionizing the tool industry. This system, characterized by its quick-change mechanism and enhanced hammering action, marked a paradigm shift in tool design. Building upon this foundation, SDS MAX chisels emerged in the 1980s, catering to heavier-duty applications that demanded greater impact force and durability.

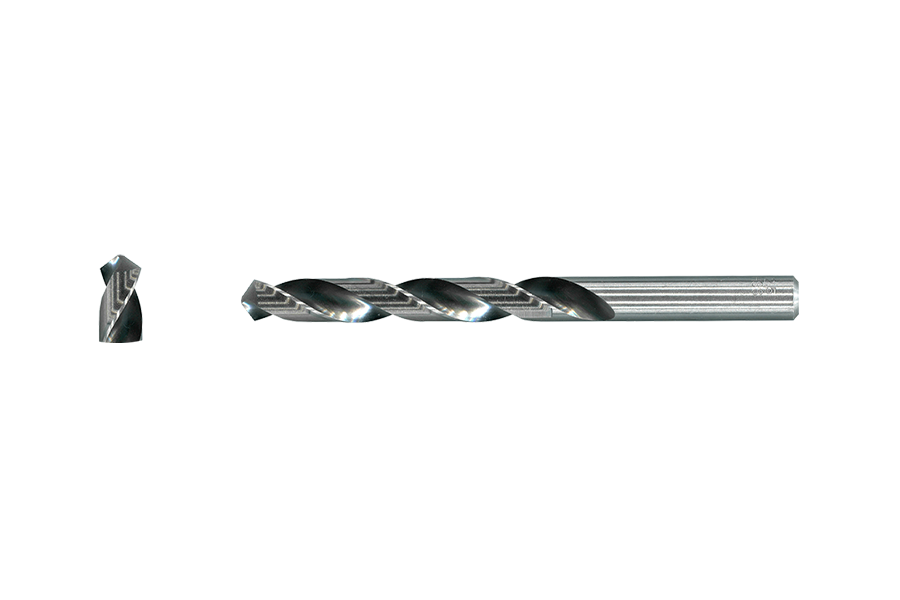

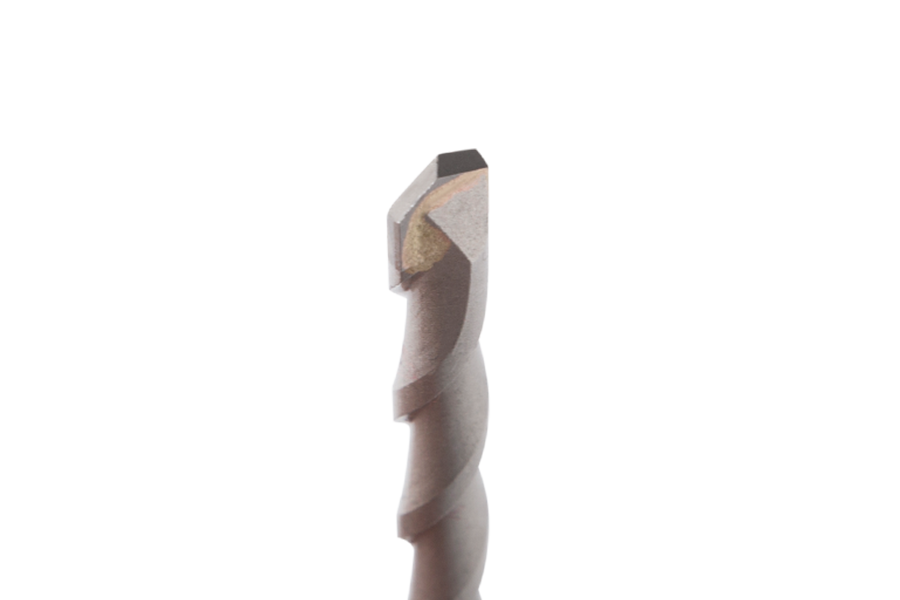

Innovative Design Features

Central to the appeal of SDS MAX chisels are their innovative design features. Unlike traditional tools that rely solely on brute force, SDS MAX chisels leverage advanced engineering principles to maximize efficiency and minimize operator fatigue. Key design elements include optimized tip geometries for precise material removal, shock-absorbing technologies to reduce vibrations, and ergonomic handles for enhanced control and comfort.

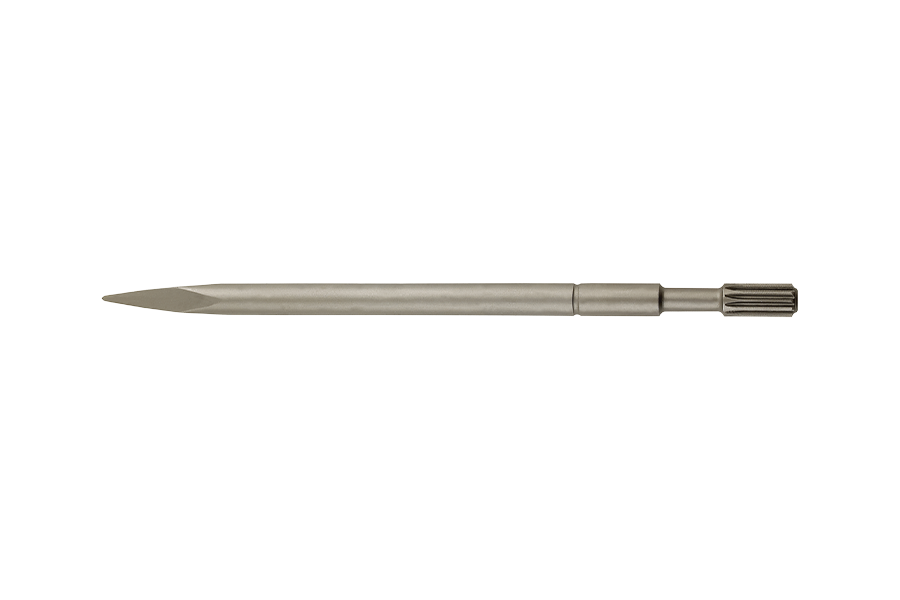

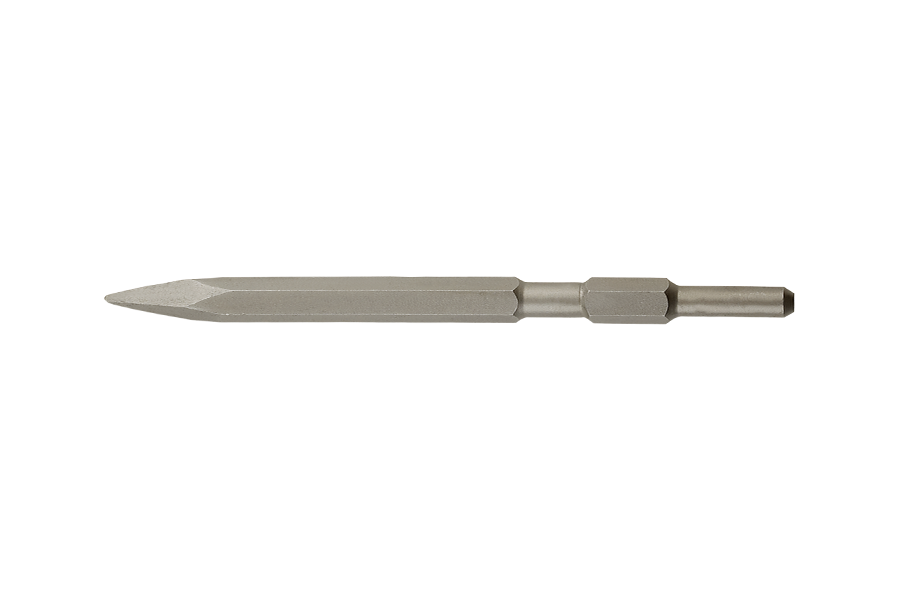

Application Versatility

The versatility of SDS MAX chisels is a testament to their adaptability across various construction disciplines. These chisels find application in concrete demolition, tile removal, surface preparation, and even artistic sculpting. The availability of different chisel types—such as pointed, flat, and wide chisels—ensures that contractors can select the right tool for the specific task at hand, thereby optimizing workflow and project timelines.

Technological Advancements

Advancements in materials science and manufacturing techniques have further propelled SDS MAX chisels into the forefront of construction technology. Modern iterations incorporate high-strength alloys and advanced heat treatment processes to enhance durability and performance. Additionally, ongoing research into vibration reduction and noise suppression technologies continues to refine the user experience, making SDS MAX chisels safer and more comfortable to operate.

Integration with Power Tools

The seamless integration of SDS MAX chisels with rotary hammers exemplifies their synergy with power tool technology. These hammers, equipped with pneumatic or hydraulic mechanisms, deliver precise, high-impact blows to the chisel tip, ensuring efficient material removal without compromising tool integrity. This integration not only enhances productivity but also expands the scope of what can be achieved on the job site.

Future Directions

Looking ahead, the future of SDS MAX chisels appears promising with ongoing innovations in automation, digitalization, and sustainability. Emerging trends such as smart tool connectivity and predictive maintenance aim to further enhance operational efficiency and reduce downtime. Moreover, a growing emphasis on eco-friendly materials and manufacturing practices underscores the industry's commitment to sustainable development.

English

English

中文简体

中文简体

Español

Español

عربى

عربى