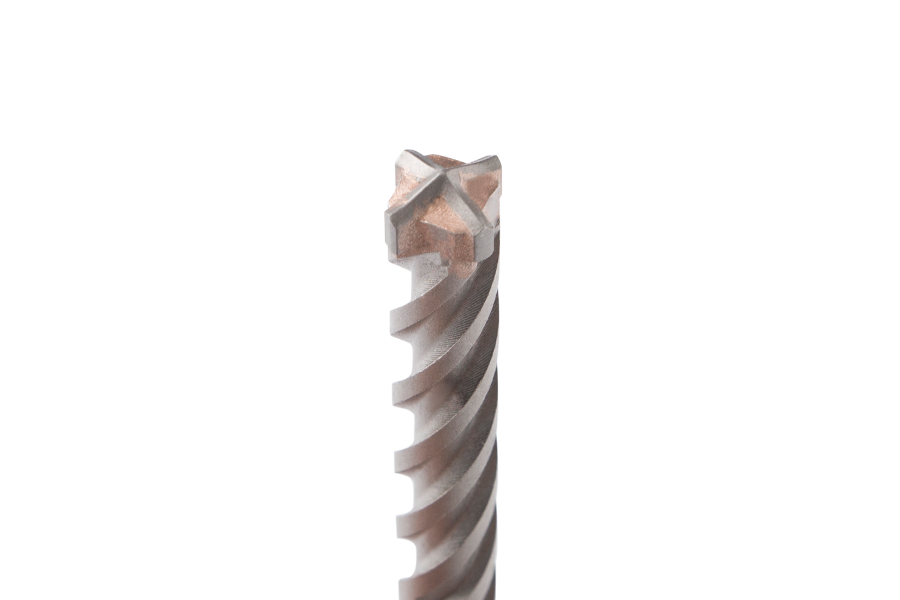

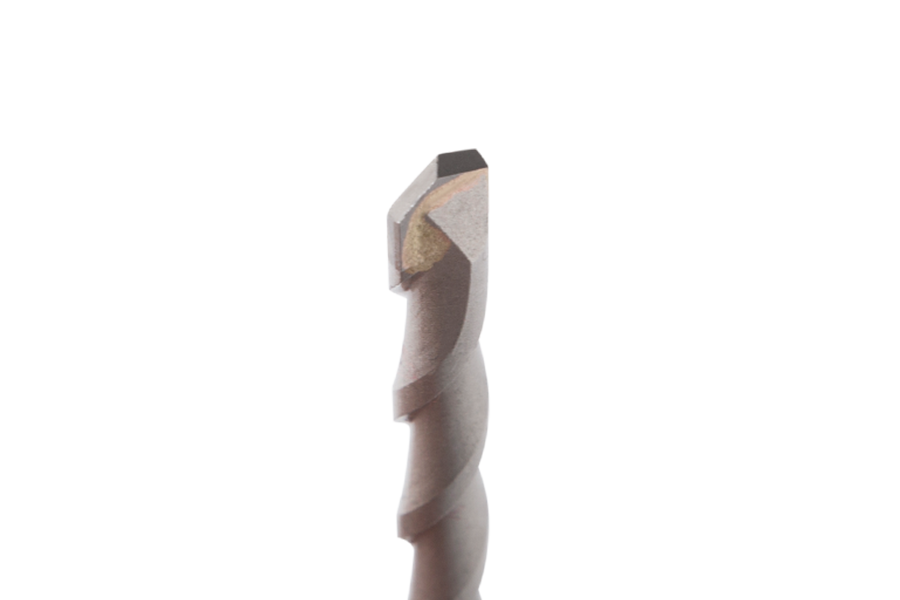

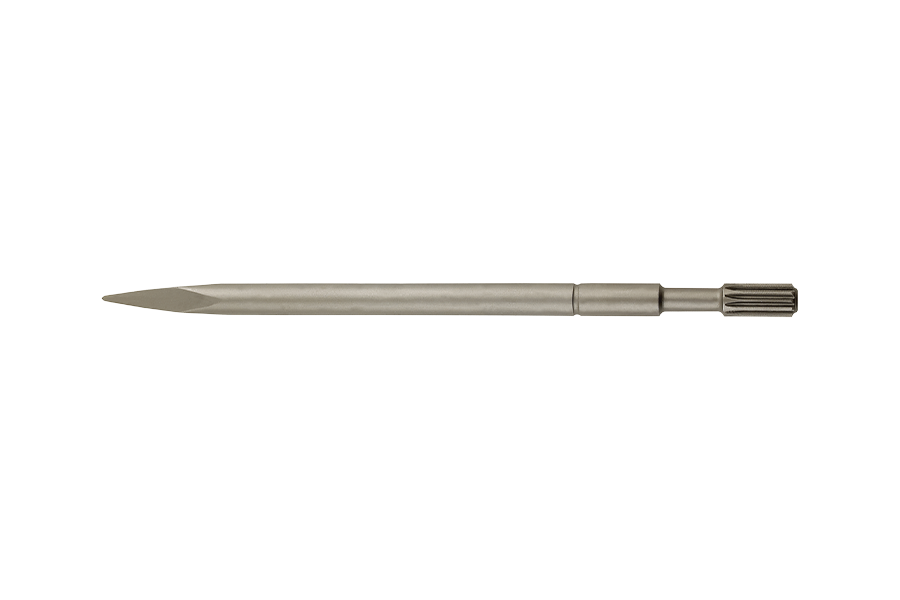

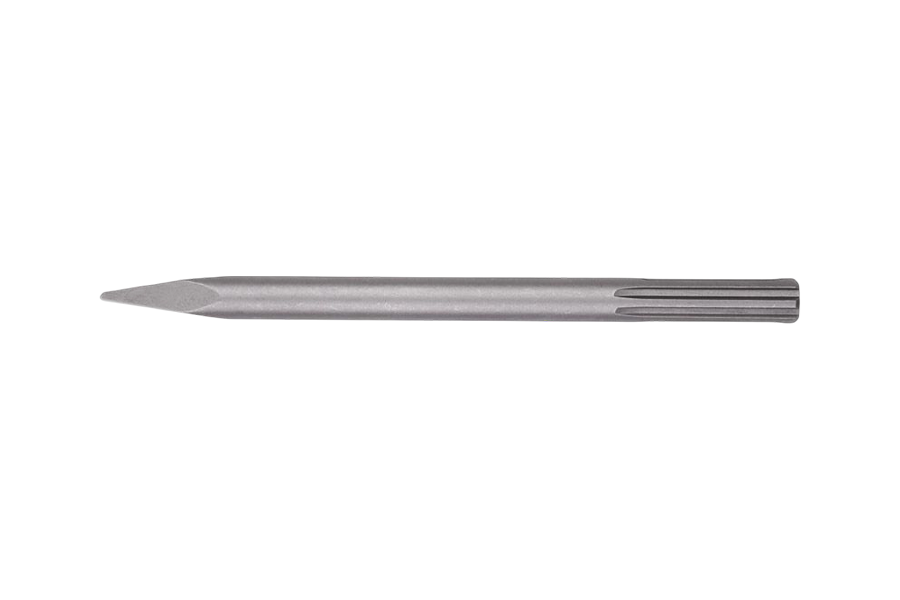

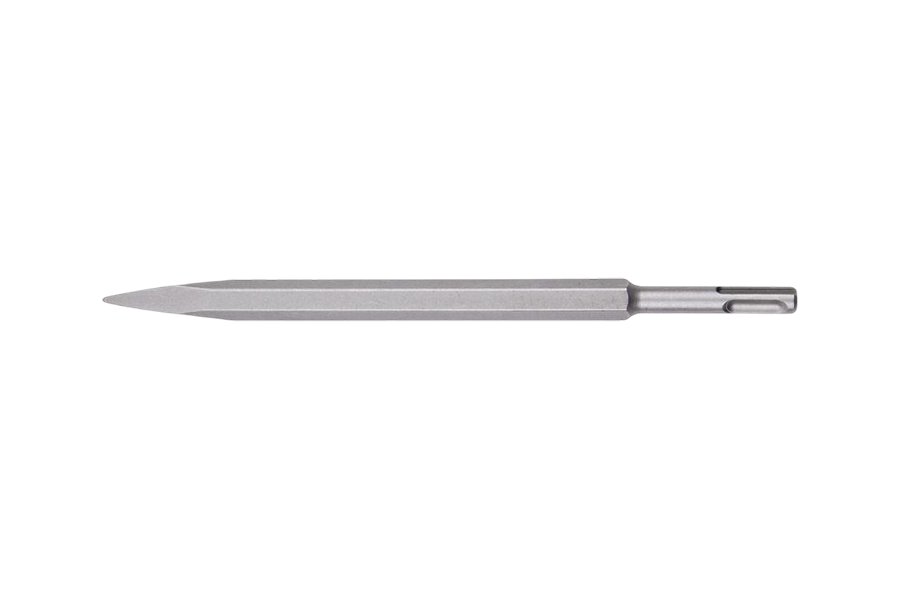

The SDS Plus shank on a drill bit serves as a connection interface between the drill bit and the chuck of a compatible power tool, typically a hammer drill. The term "SDS" stands for "Slotted Drive System," which was developed by Bosch in the 1970s to provide a more efficient and secure way to attach drill bits and other rotary tools to power tools, specifically hammer drills used for drilling into masonry, concrete, and other tough materials.

The primary purposes of the sds plus drill bit are:

Quick and Secure Attachment: The SDS Plus shank features grooves that allow for rapid and tool-free insertion and removal of the drill bit from the tool's chuck. This design ensures a secure connection between the drill bit and the tool, minimizing slippage during drilling and reducing the likelihood of accidents.

High Torque Transmission: The grooved design of the SDS Plus shank increases the surface area of contact between the drill bit and the chuck. This design, along with the use of hammer action in hammer drills, enhances the transmission of torque and impact force from the tool to the drill bit. This is particularly important when drilling into hard materials like concrete and masonry.

Efficient Hammering Action: The SDS Plus shank's design allows for the hammering action of the drill to be transferred directly to the drill bit. This feature is crucial for drilling into tough materials, as it enables the drill bit to break through the material more effectively.

Reduced Wear and Vibration: The SDS Plus system helps reduce wear on both the drill bit and the chuck by distributing the stresses more evenly. This design also helps dampen vibrations, making the drilling process more comfortable for the user and potentially extending the life of the tool.

English

English

中文简体

中文简体

Español

Español

عربى

عربى