Improving the hardness and wear resistance of the surface of a hollow hammer drill bit is essential for extending its lifespan and ensuring optimal performance when drilling into tough materials like concrete, masonry, or metal. Here are several methods to enhance the hardness and wear resistance of a hollow hammer drill bit's surface:

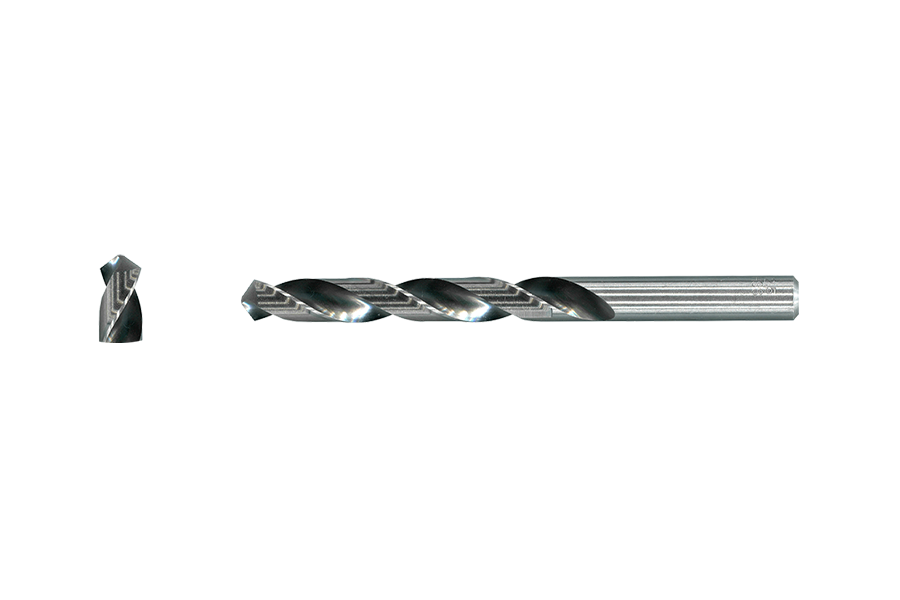

Use High-Quality Materials:

Start with high-quality materials when manufacturing the drill bit. The choice of materials, such as the type of steel for the body and tungsten carbide for the tip, significantly affects hardness and wear resistance.

Hardened Steel Body:

Ensure that the steel body of the drill bit is heat-treated and hardened. Heat treatment processes like quenching and tempering can improve the hardness and strength of the steel.

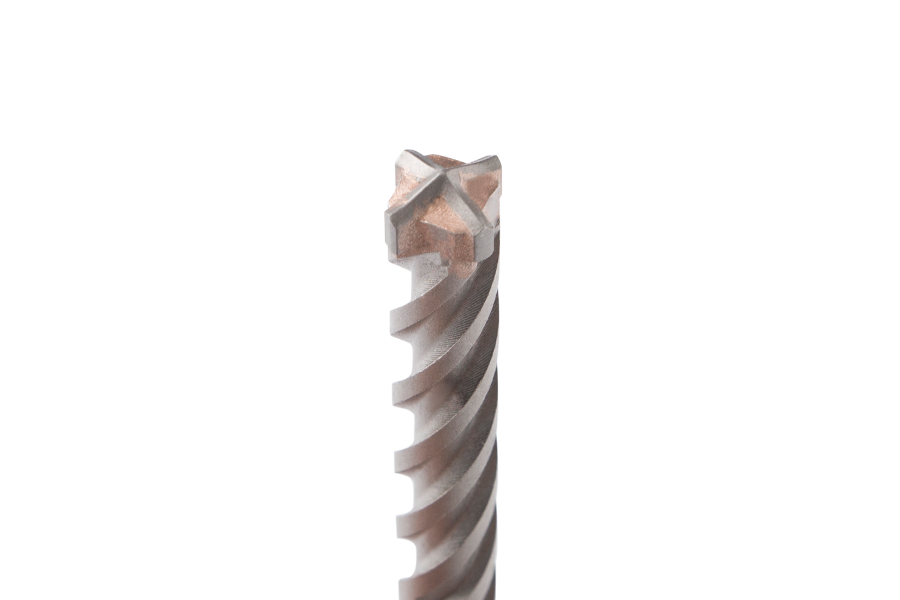

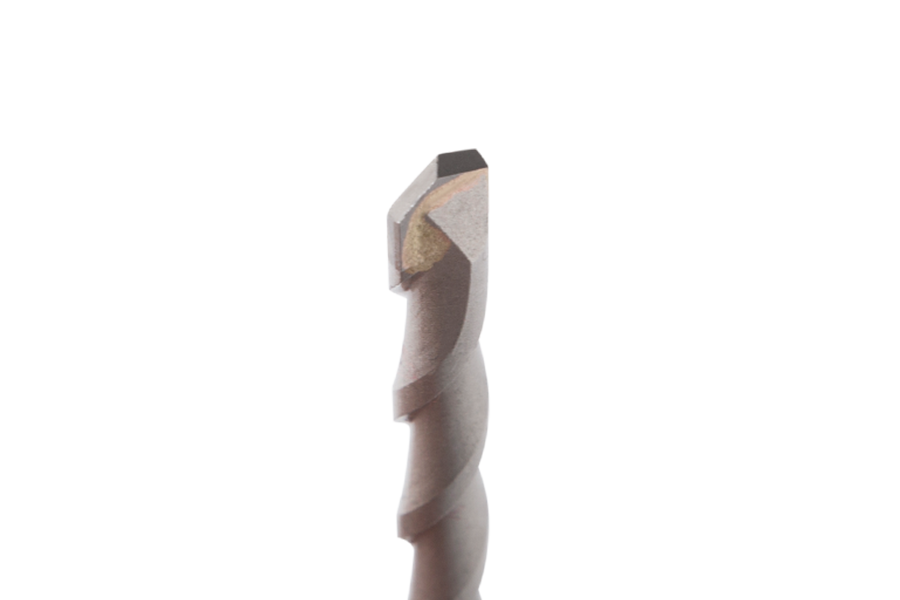

Tungsten Carbide Tips:

Tungsten carbide tips are commonly used for drill bit tips due to their exceptional hardness. Make sure the carbide tips are of high quality and properly attached to the drill bit body.

Diamond-Like Carbon (DLC) Coatings:

Apply a DLC coating to the surface of the drill bit. DLC coatings are known for their extreme hardness and low friction properties, which can significantly improve wear resistance.

Titanium Nitride (TiN) Coating:

TiN coatings can also enhance surface hardness and wear resistance. These coatings provide a protective layer that reduces friction and improves the drill bit's durability.

Carburizing:

Carburizing is a heat treatment process where carbon is diffused into the surface of the steel. This can increase surface hardness and wear resistance.

Nitriding:

Nitriding involves the introduction of nitrogen into the surface layer of the steel. This process forms hard nitride compounds on the surface, improving hardness and wear resistance.

Cryogenic Treatment:

Cryogenic treatment involves subjecting the drill bit to extremely low temperatures to enhance its material properties. This process can improve hardness and reduce wear.

Optimize Flute Design:

Design the flute geometry and configuration to optimize chip evacuation and cooling during drilling. Effective chip removal reduces friction and heat buildup, which can improve wear resistance.

Coolant or Lubricant:

Using a coolant or lubricant during drilling can reduce friction and heat generation, thus extending the life of the drill bit. Water or specialized cutting fluids can be effective.

Proper Speed and Feed Rates:

Ensure that the drill bit is used at the correct speed and feed rates for the material being drilled. Using the right parameters minimizes overheating and wear.

Regular Maintenance:

Clean and inspect the drill bit after each use to remove debris and prevent buildup. Proper maintenance can help maintain the drill bit's surface condition.

Avoid Overheating:

Avoid excessive heat generation during drilling, which can lead to premature wear. Use intermittent drilling and allow the bit to cool between holes if necessary.

Use Impact-Resistant Bits:

For hammer drilling applications, choose drill bits specifically designed to withstand impact forces. These bits are often reinforced to handle the additional stresses.

Select the Right Bit for the Material:

Different materials require different types of drill bits. Select a drill bit specifically designed for the material you are drilling to maximize performance and longevity.

By incorporating these techniques and considerations into the design, manufacturing, and use of hollow hammer drill bits, you can significantly improve their surface hardness and wear resistance, resulting in longer-lasting and more effective drilling tools.

English

English

中文简体

中文简体

Español

Español

عربى

عربى