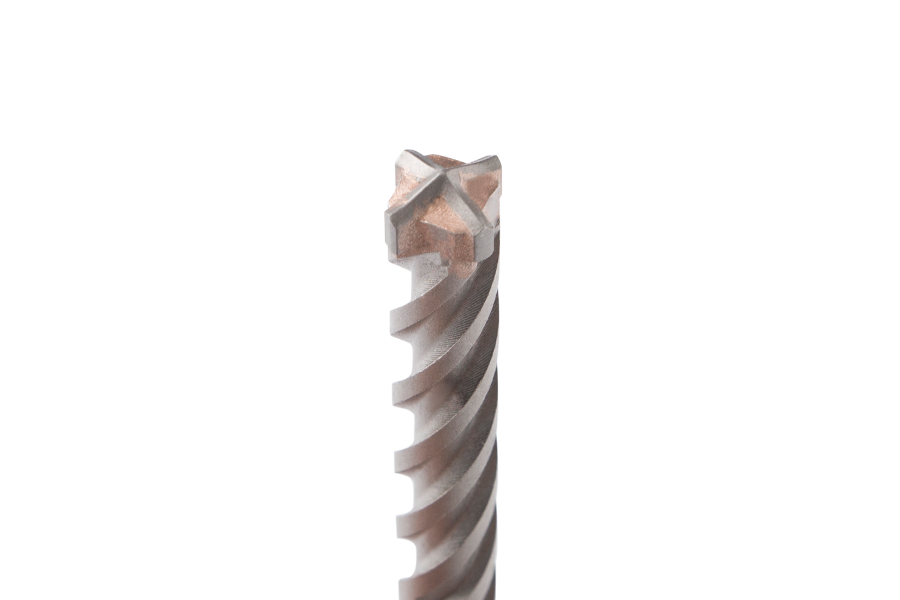

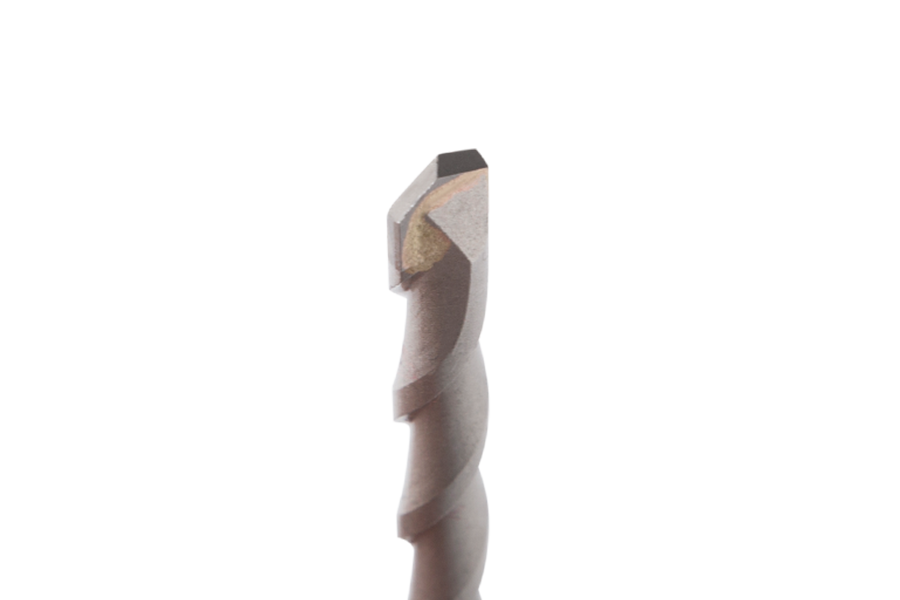

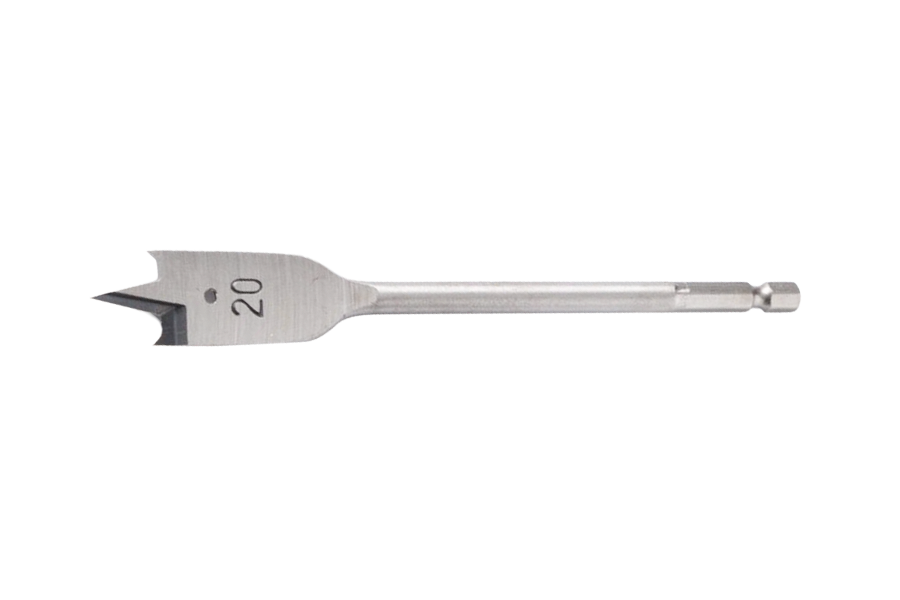

The SDS-Max drill bit itself does not play a direct role in using coolant or lubricant during drilling, as its primary function is to cut or bore through various materials. However, the choice to use coolant or lubricant and the application of these substances are important considerations made by the operator or user of the SDS-Max drill bit. The role of the operator in using coolant or lubricant during drilling is as follows:

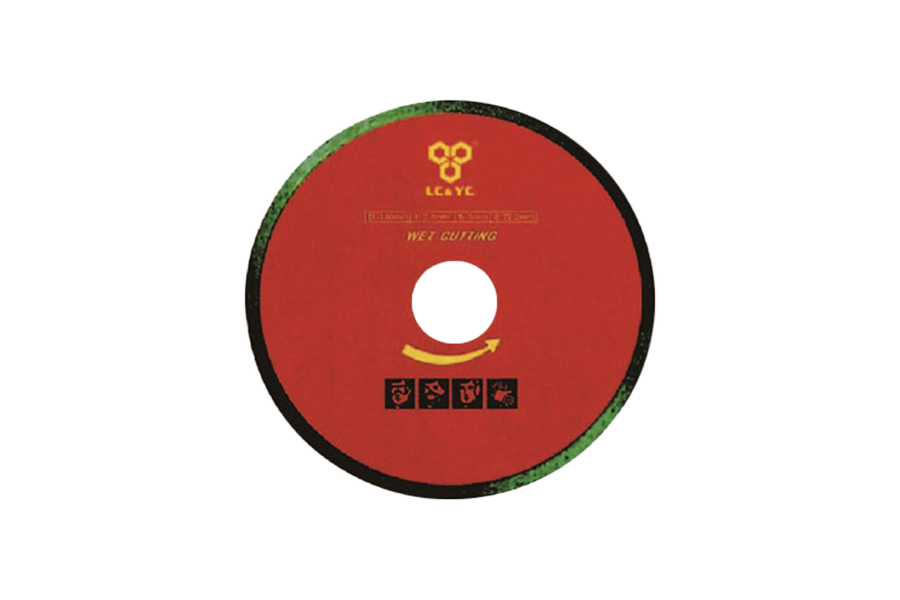

Decision to Use Coolant or Lubricant: It is up to the operator to determine whether using coolant or lubricant is necessary for the specific drilling operation. Factors such as the type of material being drilled, the depth and speed of drilling, and the potential for heat generation and friction will influence this decision.

Selection of the Right Coolant or Lubricant: If the operator decides to use coolant or lubricant, they must choose the appropriate type based on the material being drilled and the operating conditions. Different materials and drilling applications may require specific lubricants or coolants to achieve the best results.

Proper Application: The operator is responsible for applying the coolant or lubricant correctly during the drilling process. This typically involves dispensing or applying the substance to the drilling area in a manner that ensures sufficient coverage between the drill bit and the material.

Monitoring and Maintenance: Throughout the drilling operation, the operator should monitor the coolant or lubricant to ensure that it continues to provide the desired benefits. Additional application may be needed if the substance dries up or dissipates during drilling.

Safety and Cleanliness: The operator must prioritize safety when using coolant or lubricant. This includes ensuring that the work area remains safe and free of hazards, such as slippery surfaces caused by spilled lubricant. Proper disposal of used coolant or lubricant is also important for environmental and safety reasons.

Optimizing Drilling Performance: Using coolant or lubricant can help optimize the performance of the SDS-Max drill bit. By reducing heat, friction, and wear, it can enhance drilling speed, extend bit life, and improve hole quality.

Adaptation to Specific Conditions: Depending on the drilling conditions and requirements, the operator may need to adjust the type and amount of coolant or lubricant used. Some drilling operations may benefit from continuous coolant flow, while others may only require occasional lubrication.

The SDS-Max drill bit itself does not directly interact with coolant or lubricant, but its operator is responsible for deciding whether to use these substances and ensuring their correct application to achieve the desired results. Proper application of coolant or lubricant can significantly enhance the efficiency and longevity of the SDS-Max drill bit and improve the quality of the drilling operation.

English

English

中文简体

中文简体

Español

Español

عربى

عربى