When it comes to tackling tough materials like concrete, brick, or stone, a hammer drill bit is an indispensable tool in any DIY enthusiast’s or professional contractor’s arsenal. These specialized bits are engineered to withstand the intense pounding and spinning motion that a hammer drill generates, making them perfect for heavy-duty tasks that standard drill bits simply can’t handle. But what makes hammer drill bits so effective, and how do you choose the right one for your project? Let’s dig into the details.

What Sets Hammer Drill Bits Apart?

Hammer drill bits differ from regular drill bits primarily in their design and durability. While a traditional drill bit relies solely on rotational force to bore through materials, hammer drill bits are built to endure both rotational and percussive forces. This dual-action allows the drill to "hammer" the bit into the surface while simultaneously rotating it, which significantly speeds up drilling in hard materials.

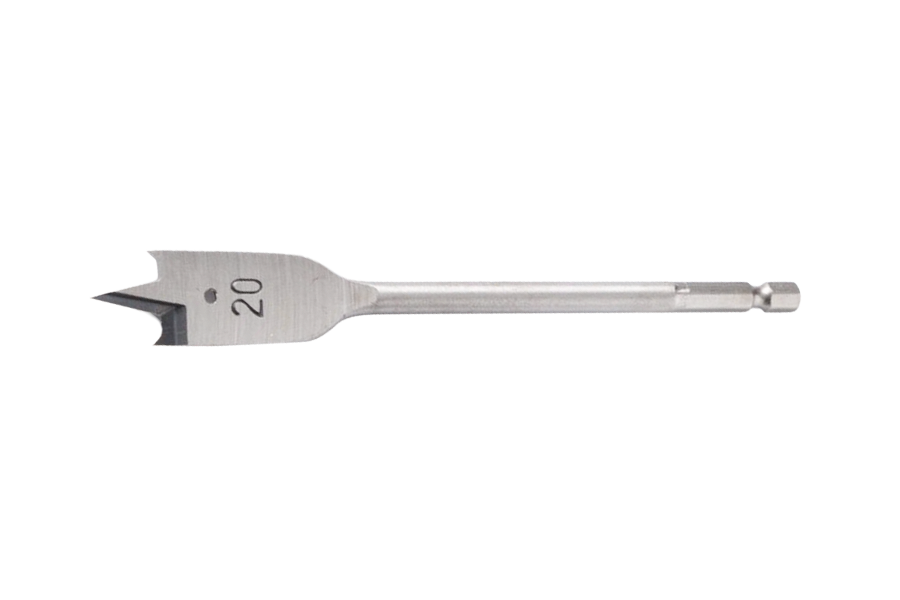

The tip of a hammer drill bit is typically made from tungsten carbide, an incredibly hard material that resists wear and tear. This ensures the bit can maintain its sharpness even after repeated use on abrasive surfaces like concrete or masonry. Additionally, the flutes—those spiral grooves along the length of the bit—are designed to efficiently remove debris from the hole as you drill, preventing clogging and allowing for smoother operation.

Choosing the Right Hammer Drill Bit

Selecting the correct hammer drill bit depends on several factors, including the material you’re working with, the size of the hole you need, and the type of hammer drill you own. Here’s a quick breakdown:

Material Matters :

If you're drilling into concrete or brick, look for bits labeled specifically for masonry work. Some hammer drill bits are also suitable for tile or stone, but these may have slightly different designs to prevent cracking or chipping.

Size and Length :

Hammer drill bits come in a variety of diameters and lengths. For most home improvement projects, a set of bits ranging from 5mm to 10mm in diameter should suffice. However, if you’re working on larger-scale construction jobs, longer and wider bits may be necessary.

Compatibility :

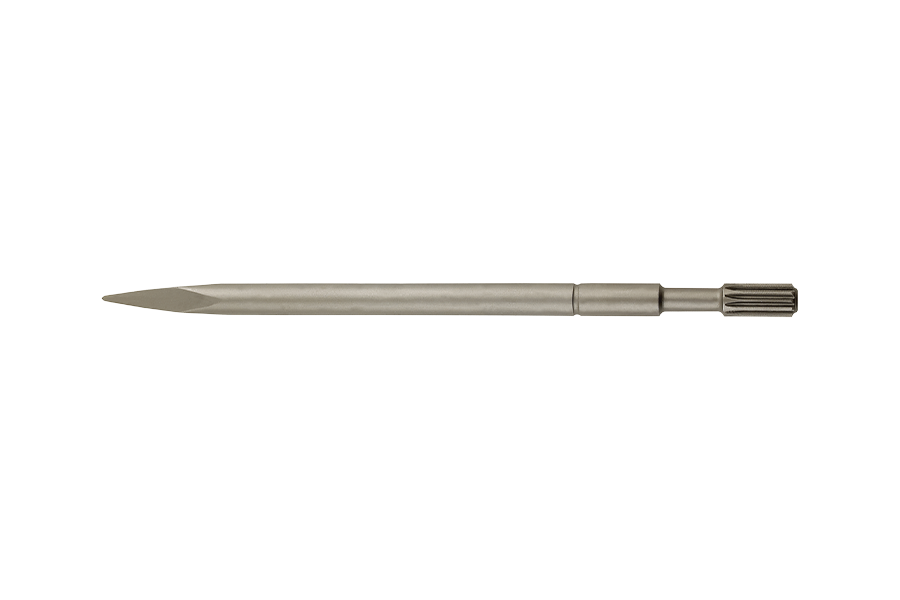

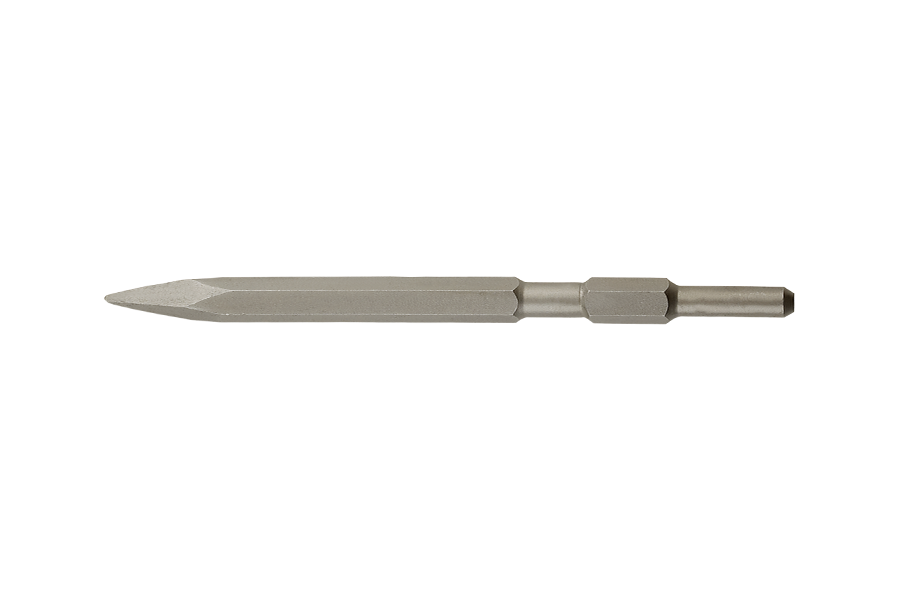

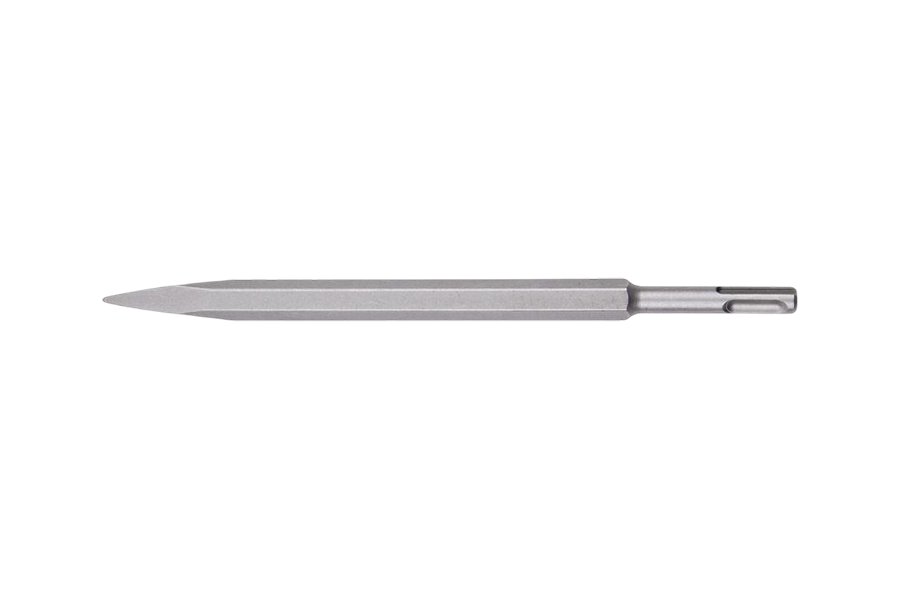

Ensure the shank (the part of the bit that fits into the drill) matches your hammer drill. SDS-plus and SDS-max are common shank types for rotary hammers, while standard round shanks are more common for lighter-duty hammer drills.

Brand and Quality :

Investing in high-quality bits from reputable brands can save you money in the long run. Cheaper bits may dull quickly or even break under pressure, leading to frustration and additional costs.

Tips for Using Hammer Drill Bits Effectively

Even the best hammer drill bit won’t perform optimally if used incorrectly. Here are some tips to get the most out of your tool:

Start Slow : Begin drilling at a lower speed to establish a pilot hole. Once the bit has a firm grip, you can increase the speed.

Apply Steady Pressure : Let the drill do the work. Applying too much force can cause the bit to overheat or become damaged.

Clear Debris Regularly : Pull the bit out occasionally to allow dust and fragments to escape, especially when drilling deep holes.

Keep It Cool : Drilling generates heat, which can wear down the bit faster. If possible, use water to cool the bit during extended drilling sessions.

Maintaining Your Hammer Drill Bits

Proper maintenance will extend the life of your hammer drill bits. After each use, clean off any dust or debris and inspect the bit for signs of wear. If the carbide tip is chipped or the flutes are excessively worn, it’s time to replace the bit. Storing your bits in a dry, organized case will also help prevent damage and keep them ready for your next project.

English

English

中文简体

中文简体

Español

Español

عربى

عربى