Solid drill bits are the unsung heroes of countless industries, from construction and manufacturing to woodworking and metalworking. These robust tools may seem simple at first glance—a cylindrical piece of hard material with flutes for cutting—but their design, function, and versatility deserve closer examination. Whether you're drilling through steel, concrete, or wood, solid drill bits serve as indispensable instruments for precision work. Their name reflects both their construction and purpose: solid in form, yet capable of creating hollow spaces.

Unlike other specialized cutting tools, solid drill bits are typically made from a single material—often high-speed steel (HSS), cobalt alloys, or tungsten carbide. This uniformity gives them exceptional strength and durability, making them suitable for tackling tough materials that would wear down softer tools. For instance, when working on hardened metals or dense surfaces like granite, a solid drill bit resists breaking under pressure while maintaining its sharpness over time.

The term "solid" also speaks to their reliability. Unlike coated or tipped drill bits, which combine different materials for enhanced performance, solid drill bits rely entirely on the inherent properties of their composition. This makes them less prone to chipping or delamination, ensuring consistent performance even after prolonged use.

Applications Across Industries

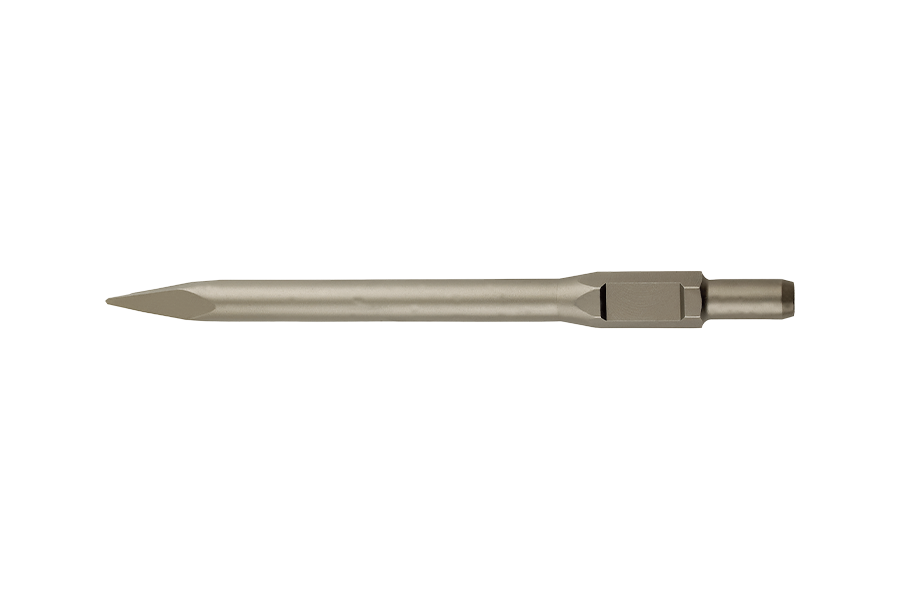

One of the standout features of solid drill bits is their adaptability across various fields. In construction, they’re used to bore holes into concrete walls or masonry structures, enabling everything from plumbing installations to electrical wiring setups. Manufacturers depend on these bits to create precise openings in metal components, allowing for seamless assembly processes. Woodworkers appreciate their ability to produce clean, accurate holes without splintering delicate grain patterns.

Even hobbyists find value in solid drill bits due to their ease of use and long lifespan. A well-maintained solid drill bit can last for years, providing excellent value for money compared to cheaper alternatives that dull quickly or require frequent replacement.

Key Design Features

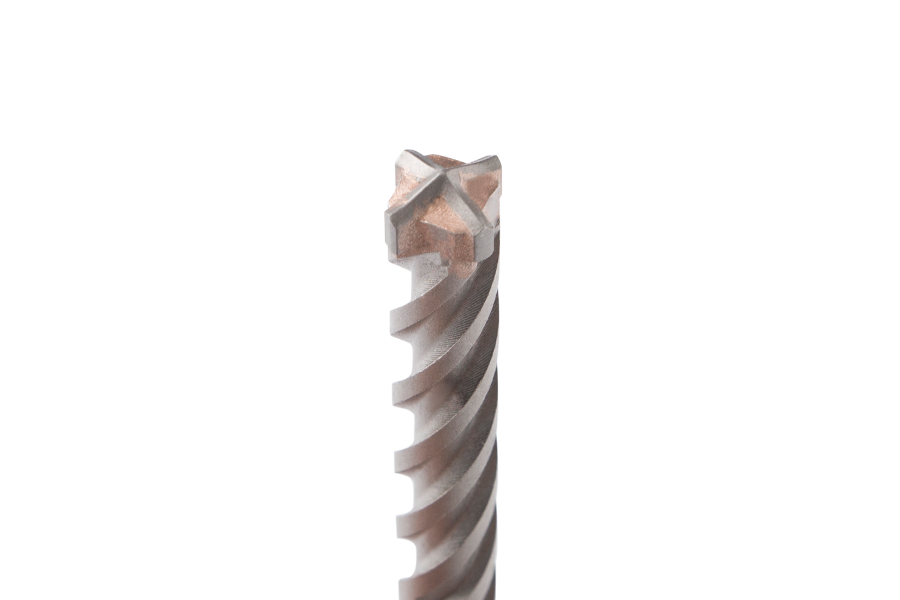

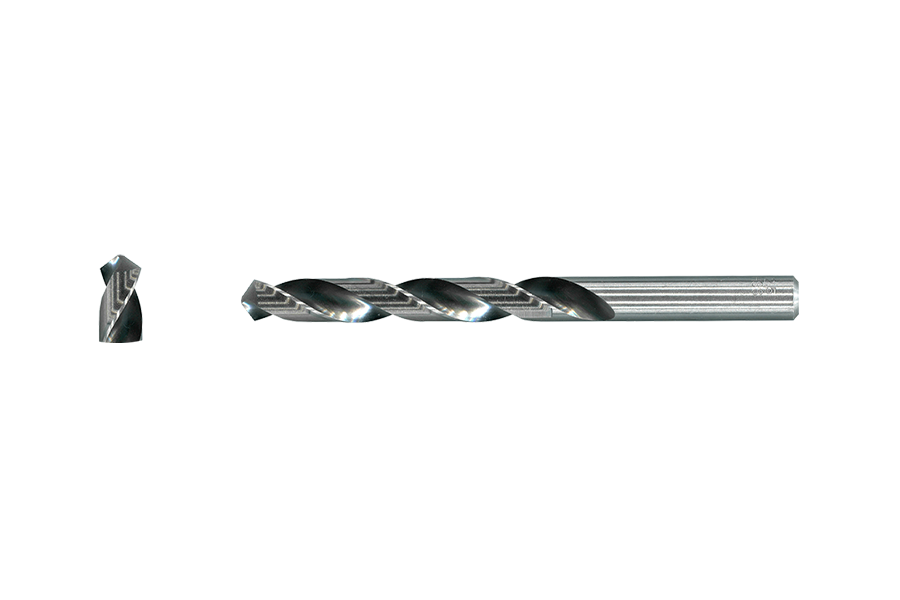

While all drill bits share some common characteristics, solid drill bits stand out because of specific design elements tailored to maximize efficiency. The spiral flutes along the body help evacuate chips and debris during operation, preventing clogging and reducing friction. This not only improves speed but also extends the tool's life by minimizing heat buildup.

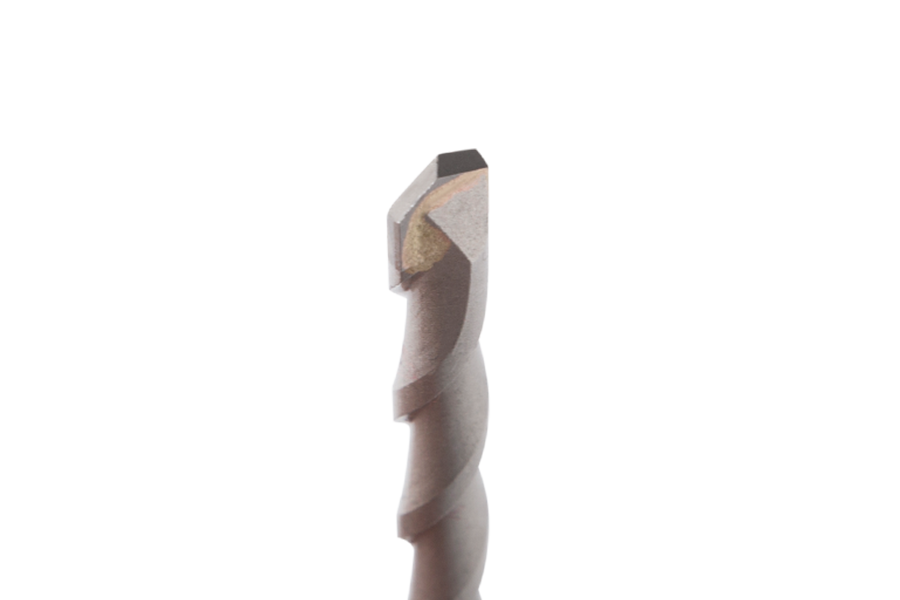

Additionally, the tip geometry varies depending on the intended application. For example, split-point tips eliminate the need for pre-drilling pilot holes by starting accurately on contact, while flat-bottomed designs excel at countersinking tasks. These subtle variations highlight how engineers continually refine solid drill bits to meet evolving needs.

Choosing the Right Material

Selecting the appropriate material for your solid drill bit depends largely on the job at hand. High-speed steel (HSS) bits are versatile enough for general-purpose drilling in wood, plastic, and mild steel. Cobalt-infused HSS offers superior heat resistance, ideal for tougher metals like stainless steel or titanium. Meanwhile, tungsten carbide-tipped bits deliver unmatched hardness, perfect for concrete, brick, or tile.

Each material has trade-offs regarding cost, longevity, and suitability for certain projects. Understanding these differences ensures you choose the best tool for the task, balancing performance with budget constraints.

Maintenance Tips for Longevity

To get the most out of your solid drill bits, proper care is essential. Regular cleaning removes built-up residue that can dull the cutting edges, while occasional sharpening restores their effectiveness. Storing them in protective cases prevents accidental damage and keeps them organized for quick access.

It’s also important to match the drill speed to the material being drilled. Too fast, and excessive heat will degrade the bit; too slow, and inefficient cutting may occur. Using lubricants or coolants when working with hard materials further reduces wear and tear, extending the bit’s operational lifespan.

English

English

中文简体

中文简体

Español

Español

عربى

عربى