1. Identify the Material You’re Drilling Into

The first and most important factor to consider when choosing a hammer drill bit is the material you're drilling into. Different hammer drill bits are designed for specific materials, and using the wrong type can result in poor performance, shorter lifespan, and even tool damage.

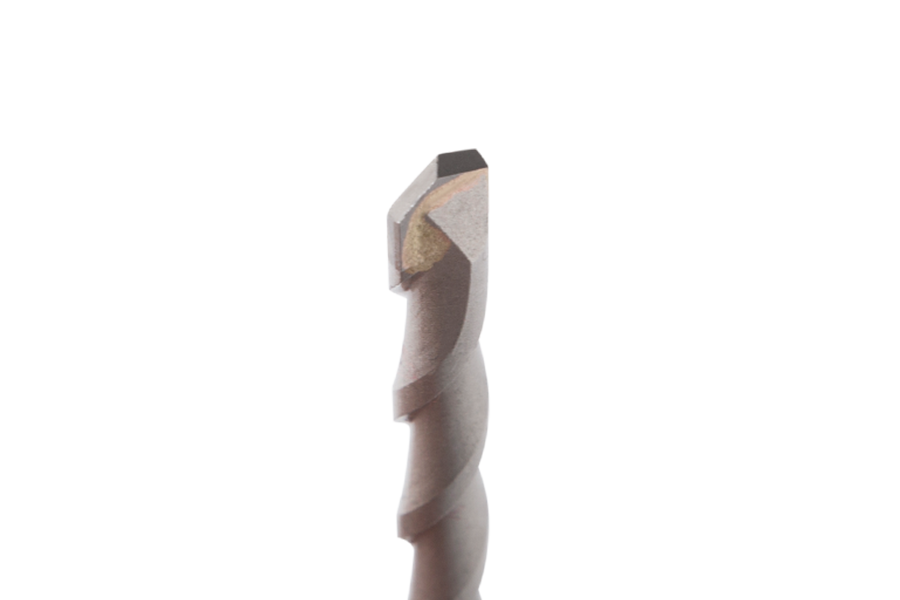

Concrete and Masonry: For drilling into concrete, brick, or stone, you will need a carbide-tipped hammer drill bit or a SDS bit. These bits are designed to withstand the intense impact and friction generated when drilling through hard materials.

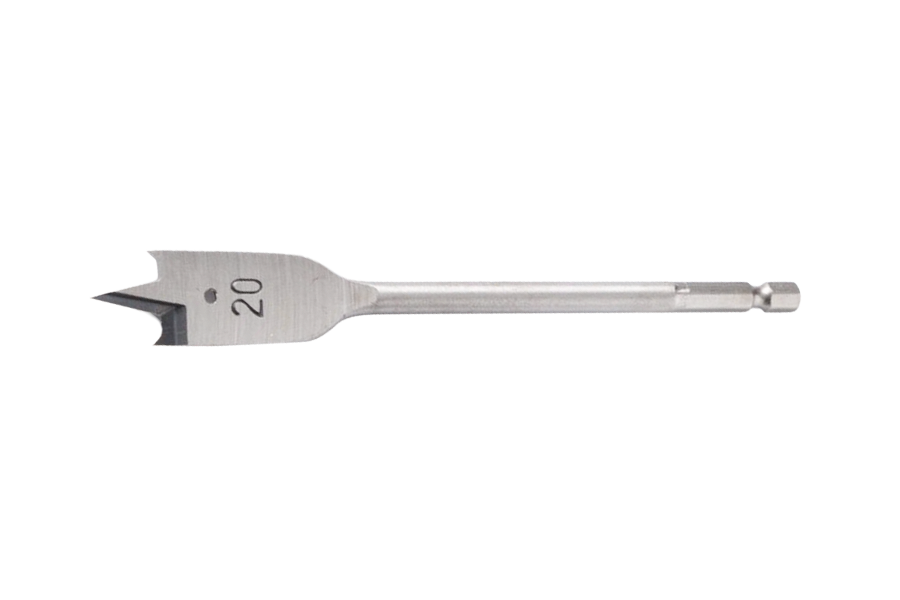

Wood or Plastic: For softer materials, you may not need a hammer drill bit at all. A standard drill bit or wood bit will suffice. However, if you’re using a hammer drill on softer materials, choose a bit that offers a balance of sharpness and strength.

Metal: When drilling into metal, you’ll need a metal drill bit. While a hammer drill can be used for some metals, it’s generally better suited for tougher surfaces like concrete and masonry.

2. Choose the Right Shank Type

Hammer drill bits come with different shank types that are compatible with specific drills. The most common types include:

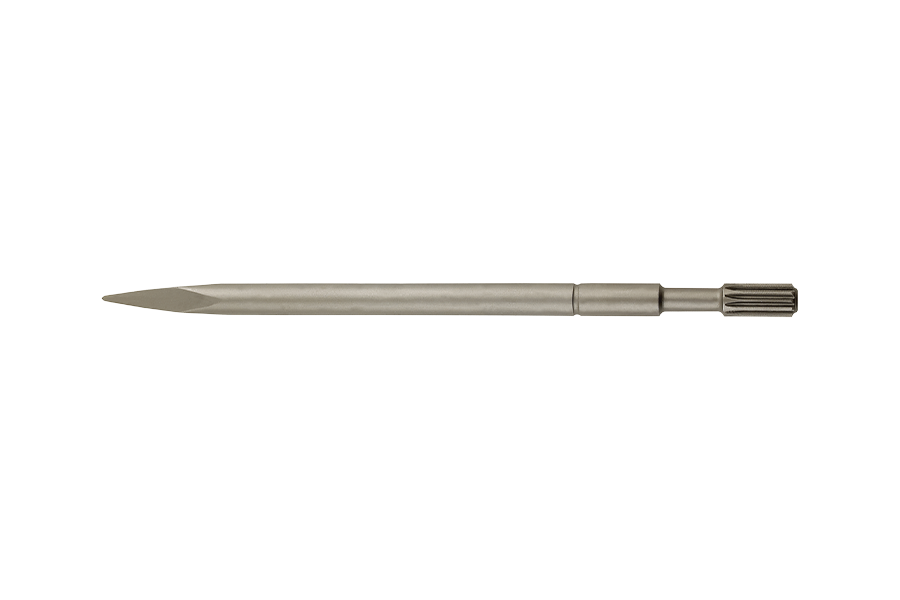

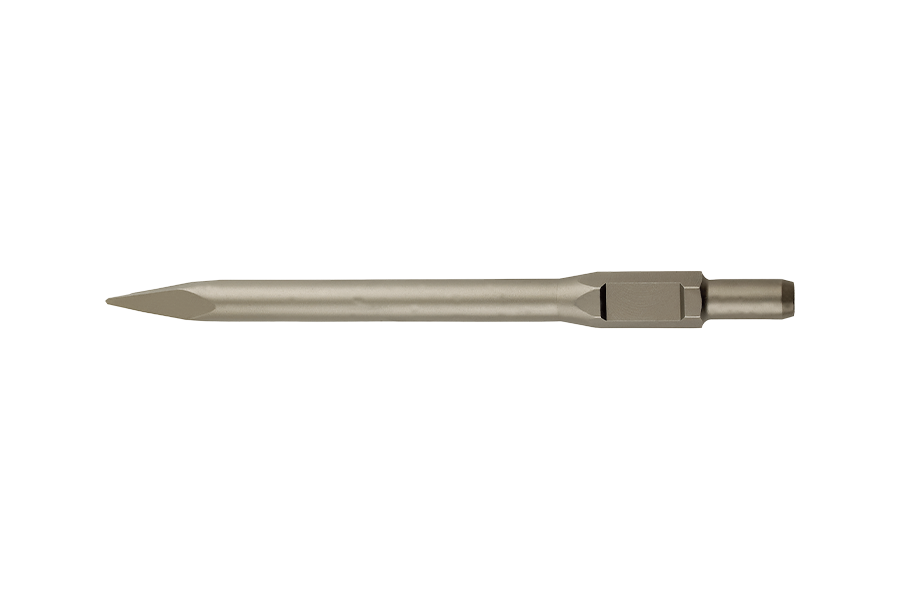

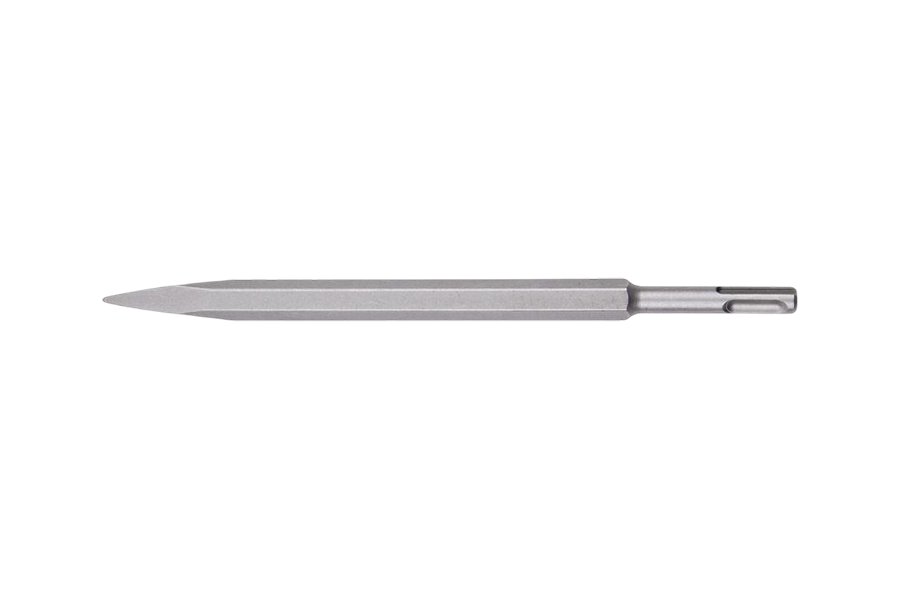

SDS Shank: Ideal for use with rotary hammer drills, SDS bits provide superior power transfer and stability. They are commonly used for heavy-duty masonry work.

Straight Shank: Straight shank bits can be used with most drill types and are ideal for general-purpose drilling tasks.

Hex Shank: Hex shank bits provide a secure grip, ensuring that the bit doesn’t slip during use. These bits are excellent for precise drilling and often used in impact drivers.

3. Consider the Bit Size and Length

The size and length of the hammer drill bit will depend on the depth and diameter of the hole you need to create. Shorter bits are typically used for shallower holes, while longer bits are necessary for drilling deeper holes. Ensure the bit size matches the specifications required for your project.

4. Look for Durability and Performance Features

Durability is a key factor in choosing the right hammer drill bit. Look for bits that are made from high-quality materials such as carbide, tungsten, or diamond-coated tips for enhanced durability and performance. Bits with spiral flute designs are also ideal as they help to remove debris more effectively during drilling, reducing the chances of clogging and overheating.

English

English

中文简体

中文简体

Español

Español

عربى

عربى