The Anatomy of a Wood Drill Bit

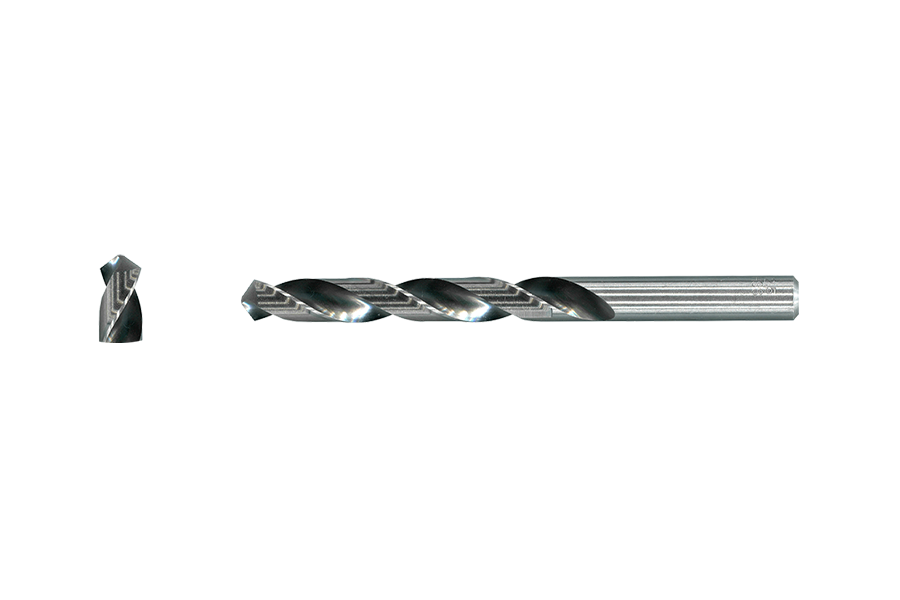

At its core, a wood drill bit is a cutting tool designed to remove material as it rotates into the workpiece. While the design can vary significantly across different types of drill bits, the basic components remain the same:

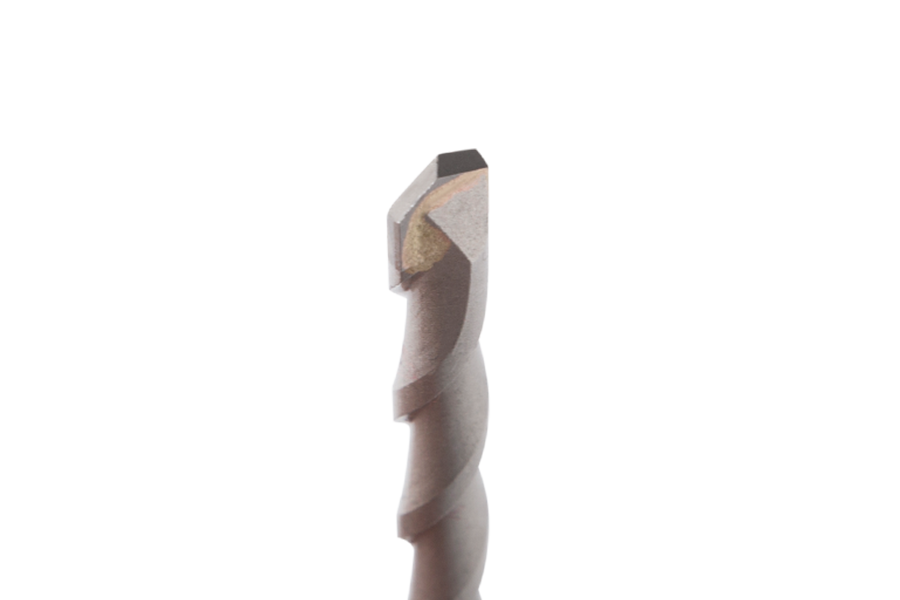

Point: The tip of the bit is the first part to make contact with the wood. Its design plays a critical role in how effectively the bit cuts into the material. For instance, a sharp, well-designed point ensures easy entry into the wood.

Flutes: These are the spiral grooves along the length of the bit. The flutes play a crucial role in removing the wood shavings that are cut during drilling. A smooth flute design helps minimize friction and improves the overall efficiency of the bit.

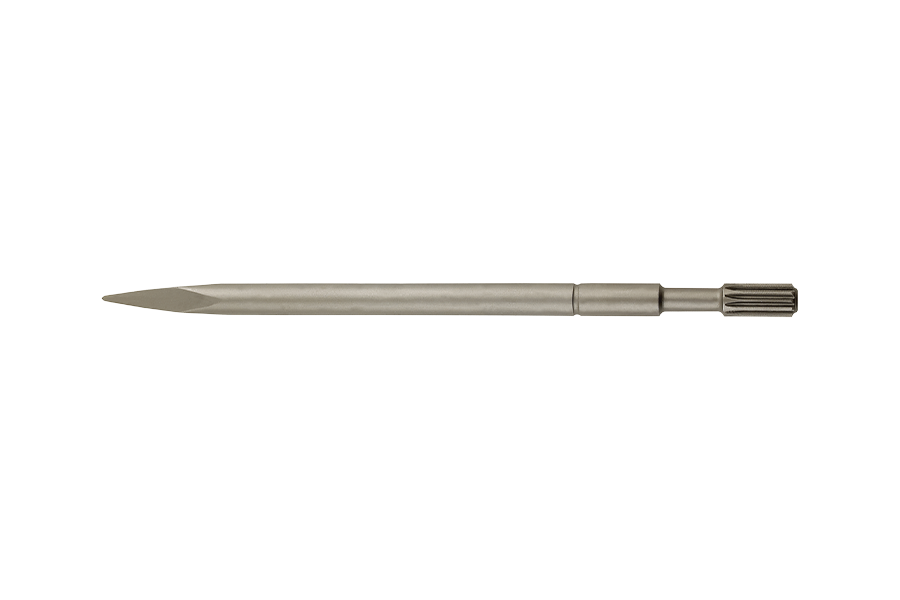

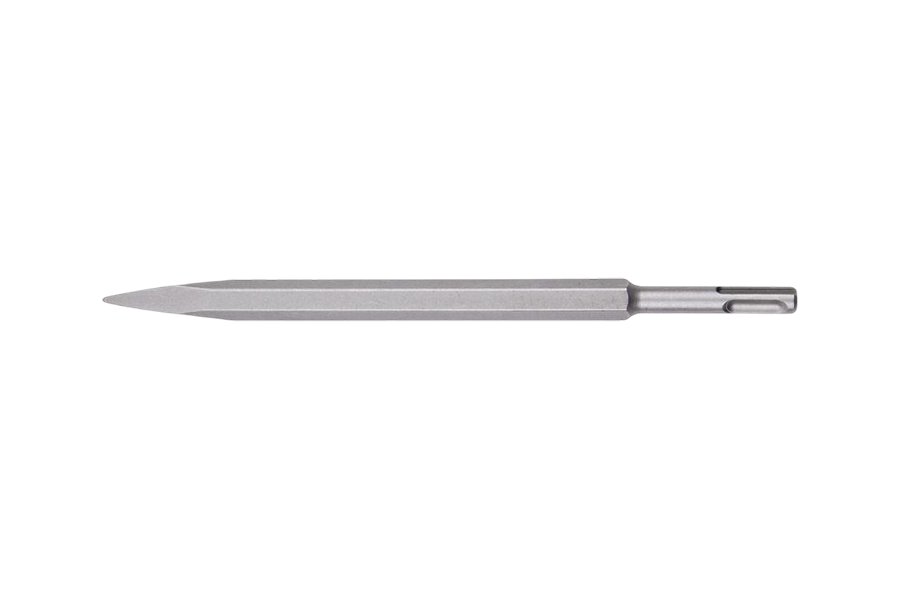

Shank: The shank is the part of the drill bit that fits into the drill. It can be round or hexagonal, depending on the type of drill being used.

How Wood Drill Bits Cut Through Wood

The cutting process begins as the wood drill bit is powered by a drill, spinning rapidly at high speeds. As the bit’s point makes contact with the wood, it begins to carve out material. The flutes then channel the cut wood chips away from the hole, preventing blockages and ensuring a smooth drilling process.

The speed and rotation of the drill bit are crucial to its performance. Drilling too slowly can cause excessive friction, which can burn the wood and dull the bit. On the other hand, drilling too quickly can overheat the bit, leading to premature wear and tear.

Factors That Affect the Cutting Performance

Several factors determine how well a wood drill bit performs:

Material Hardness: Different wood species vary in density and hardness. Softer woods, like pine, are easier to drill into, while hardwoods like oak require more robust and sharper bits. The design of the bit is often tailored to handle specific wood hardness levels.

Drill Speed: The optimal speed at which a drill bit operates depends on the material being drilled and the type of bit. For instance, auger bits typically require slower speeds for deeper cuts, while twist bits can handle faster speeds for lighter tasks.

Bit Sharpness: A sharp drill bit is essential for clean and precise drilling. As bits dull over time, they struggle to cut through the wood effectively, which can result in jagged edges and more resistance.

The Types of Wood Drill Bits and Their Applications

Understanding the different types of wood drill bits is key to achieving the best results in your projects:

Twist Drill Bits: These are versatile and commonly used for drilling holes in a variety of materials, including wood. Their spiral design ensures effective chip removal, making them ideal for smaller diameter holes.

Spade Bits: Designed for larger holes, spade bits are flat with a sharp, pointed tip. These bits can cut quickly through wood, but their design tends to leave a rougher finish.

Forstner Bits: Known for creating flat-bottomed, precise holes, Forstner bits are great for applications where smooth, clean cuts are necessary, such as in doweling or hinge placements.

Auger Bits: Auger bits are excellent for deep drilling in wood. The spiral flute design allows for the efficient removal of large amounts of wood, making them perfect for creating deep holes.

English

English

中文简体

中文简体

Español

Español

عربى

عربى