Hammer drill bits can be classified based on several factors, including the type of shank, the material they are designed to drill into, and the shape of the tip. Here are some common classifications of hammer drill bits:

Shank Type:

a. SDS-Plus: SDS-Plus is a common shank type used in hammer drills. It features a cylindrical shank with two open grooves on the sides, allowing the bit to slide into the drill's chuck and lock securely in place.

b. SDS-Max: SDS-Max is a larger and heavier-duty shank type primarily used in heavy-duty hammer drills. It has a larger diameter and features slots on the sides, similar to SDS-Plus, but with larger dimensions.

c. Hex: Hex shank bits have a hexagonal shape that fits into the chuck of a hammer drill. They are commonly used in combination with impact drivers and can be quickly changed using a quick-release mechanism.

Material:

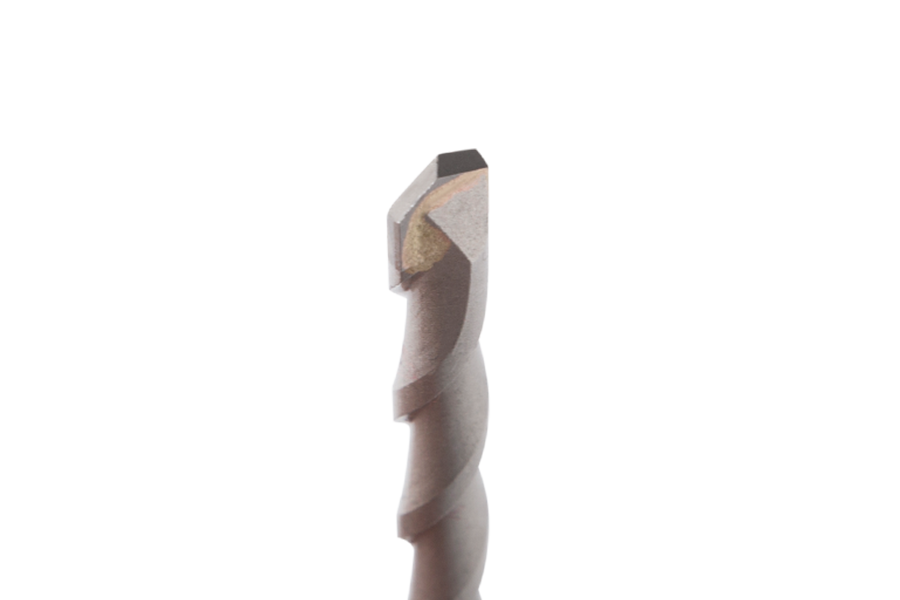

a. Masonry Bits: Masonry bits are designed to drill into various masonry materials such as concrete, brick, stone, or tile. They typically have a carbide or tungsten carbide tip for enhanced durability and efficient drilling in tough materials.

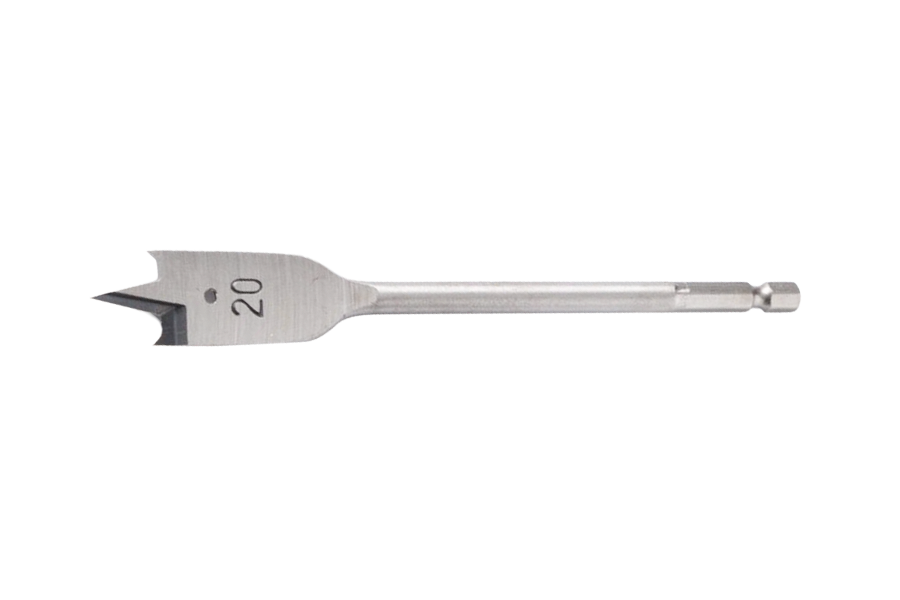

b. Wood Bits: Wood bits are specifically designed for drilling into wood and wooden materials. They usually have a pointed or spade-like tip and may feature flutes to remove chips and debris during drilling.

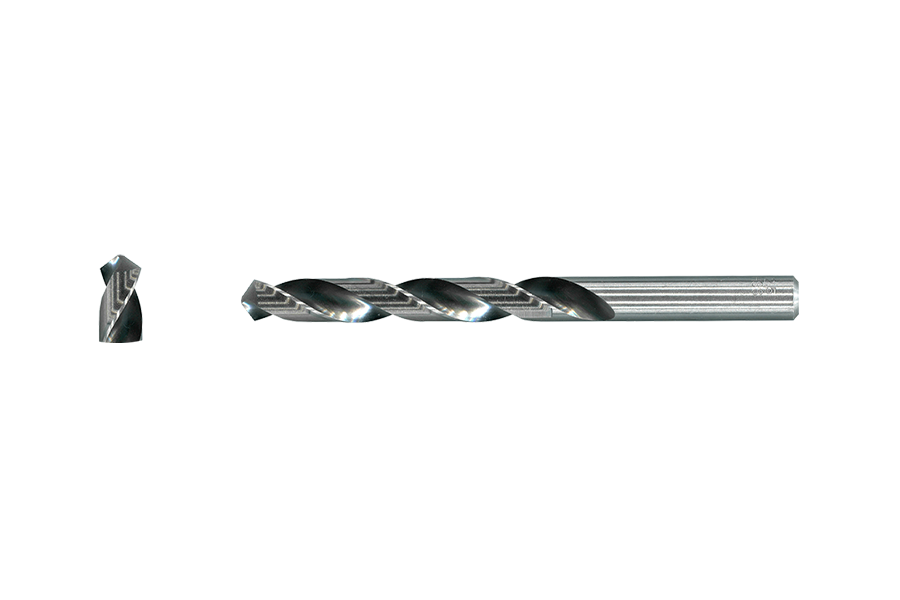

c. Metal Bits: Metal bits are used for drilling into metal surfaces. They often have a high-speed steel (HSS) construction or may feature cobalt or titanium coatings for increased durability and heat resistance.

Tip Shape:

a. Flat Tip: Flat-tipped hammer drill bits have a straight cutting edge and are commonly used for drilling into wood or plastic materials.

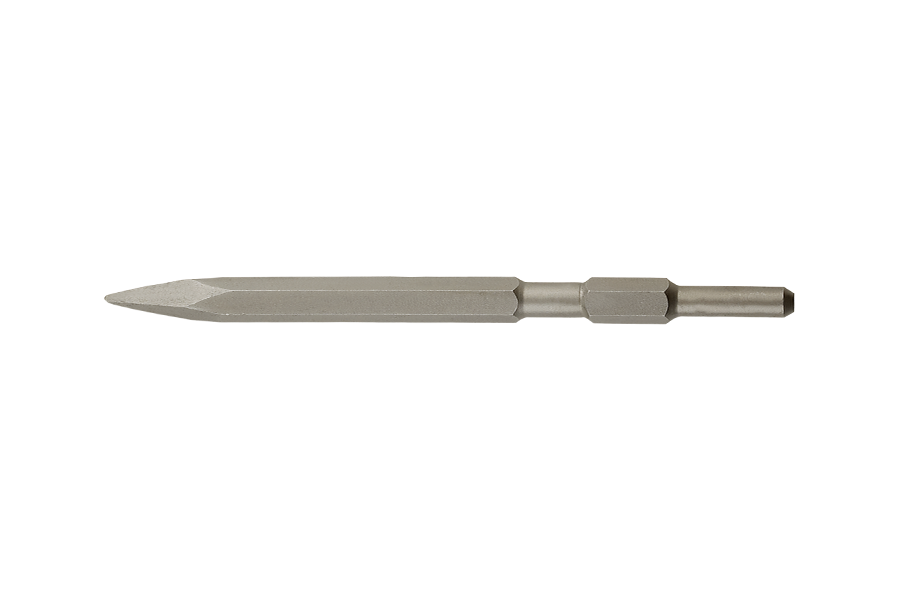

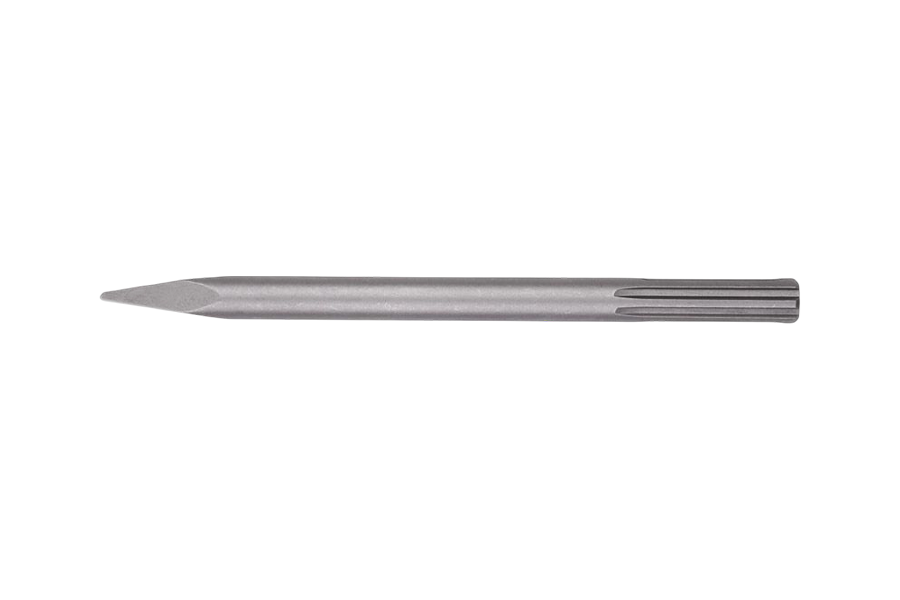

b. Pointed Tip: Pointed-tipped bits have a sharp, conical tip and are typically used for initial hole positioning in various materials before switching to a different type of bit for drilling.

c. Carbide Tip: Carbide-tipped bits feature a tip made of carbide, which is extremely hard and durable. They are commonly used for drilling into masonry and other tough materials.

Specialty Bits:

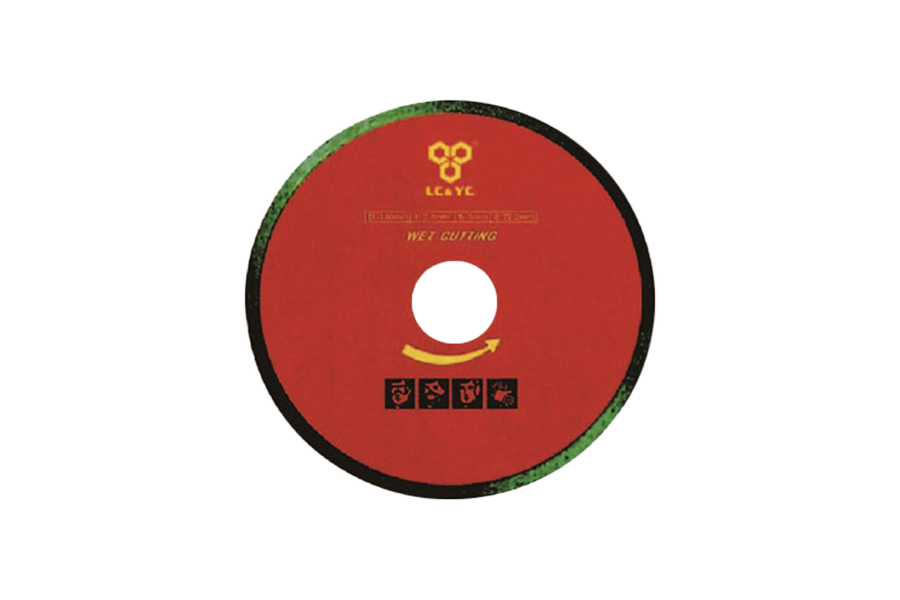

a. Tile Bits: Tile bits are specifically designed for drilling into ceramic tiles, porcelain, or glass. They have a carbide or diamond-coated tip for precise and clean drilling without damaging the tile.

b. Multi-purpose Bits: Some hammer drill bits are designed for versatility, allowing drilling into multiple materials such as wood, metal, and masonry. These bits typically have a combination of features and materials to handle various drilling tasks.

Besides,Hammer drill bits are versatile tools that are used with a hammer drill to create holes in various materials. Their application depends on the type of bit and the material being drilled. Here are some common applications of hammer drill bits:

Masonry and Concrete: Hammer drill bits with carbide or tungsten carbide tips are specifically designed for drilling into masonry materials such as concrete, brick, stone, or tile. They are commonly used in construction, renovation, and DIY projects for tasks like installing anchors, fasteners, or creating openings for pipes and electrical wires.

Woodworking: Wood drill bits are used with hammer drills for drilling holes in wooden materials. They are commonly used in woodworking projects, furniture making, and carpentry tasks. Wood bits with a spade or flat tip are suitable for general-purpose drilling in wood.

Metal: Metal drill bits, often made of high-speed steel (HSS) or with coatings like cobalt or titanium, are used for drilling into metal surfaces. They are commonly used in metalworking, fabrication, or DIY projects that involve drilling holes in metal sheets, pipes, or components.

Tile and Glass: Tile drill bits, often featuring a carbide or diamond-coated tip, are designed for drilling into ceramic tiles, porcelain, or glass. They provide precise and clean drilling without damaging the tile or glass surface. These bits are commonly used in tile installation, bathroom renovations, or decorative glass projects.

General Purpose: Some hammer drill bits are designed for general-purpose drilling and can be used with multiple materials. These bits typically have a versatile design and may feature a combination of materials such as HSS or carbide tips. They are suitable for tasks where drilling is required in different materials, such as drilling through wood, masonry, or metal in a single project.

Specialized Applications: In addition to the common applications mentioned above, there are specialized hammer drill bits available for specific tasks. These can include long-length bits for deep drilling, auger bits for creating large-diameter holes, hole saws for cutting holes of specific sizes, or chiseling bits for light chiseling or demolition tasks.

English

English

中文简体

中文简体

Español

Español

عربى

عربى