SDS Plus chisels are commonly used in construction and demolition applications for chiseling, breaking, and removing materials such as concrete, masonry, and stone. The structure of an SDS Plus chisel typically consists of the following components:

Shank: The shank is the main body of the chisel that connects to the power tool. In the case of SDS Plus chisels, the shank is designed with a special SDS Plus system, which includes two open grooves and two ball bearings on the shank end. This system allows for quick and secure attachment of the chisel to the SDS Plus chuck of the power tool, ensuring efficient power transfer and preventing slippage during operation.

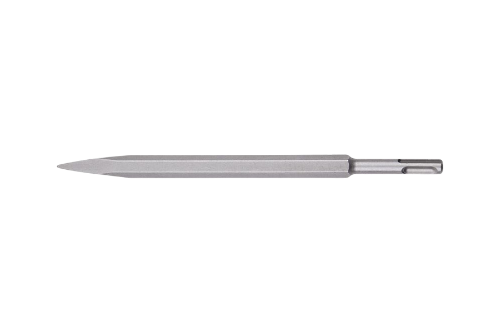

Head: The head is the working end of the chisel and is designed to perform specific tasks. The shape and design of the head can vary depending on the intended application. Common types of SDS Plus chisel heads include:

Flat Chisel: This type of head has a flat, wide cutting edge and is used for general-purpose chiseling, breaking, and leveling tasks.

Pointed Chisel: This type of head has a sharp, pointed tip and is used for precise breaking, chipping, and starting holes in hard materials.

Scaling Chisel: This type of head has a wide, tapered shape with a flat cutting edge and is specifically designed for removing scale, rust, or paint from surfaces.

Blade: The blade refers to the cutting edge or striking surface of the chisel head. It is typically made of hardened steel or other durable materials to withstand the forces and impacts during chiseling. The blade may have various profiles and angles depending on the specific application and desired cutting action.

Flutes: Flutes are the grooves or channels on the sides of the chisel head. They serve two main purposes. First, the flutes help to remove debris and dust generated during chiseling, allowing for better visibility and preventing clogging. Second, the flutes provide structural strength to the chisel head, ensuring stability and durability during heavy-duty applications.

Heat Treatment: To enhance the strength and durability of the chisel, the blade and other critical components may undergo heat treatment processes. Heat treatment involves subjecting the material to controlled heating and cooling to modify its properties, making it tougher and more resistant to wear, bending, and chipping.

Meanwhile,SDS Plus chisels serve various functions in construction and demolition applications. Here are the main functions of SDS Plus chisels:

Chiseling and Breaking: SDS Plus chisels are primarily used for chiseling and breaking tasks. The sharp cutting edge or pointed tip of the chisel head allows for precise and controlled chiseling, such as removing concrete, masonry, or stone. They are effective in breaking through tough materials and creating clean, straight edges or channels.

Demolition: SDS Plus chisels are commonly used in demolition work. They are effective for breaking apart concrete structures, removing old tiles, or demolishing walls. The robust design and durable construction of SDS Plus chisels enable them to withstand the high impact forces generated during demolition tasks.

Channeling and Grooving: SDS Plus chisels are also used for creating channels or grooves in hard materials. They can be used to cut channels for electrical wiring, plumbing pipes, or decorative purposes. The width and shape of the chisel head can be selected to achieve the desired groove dimensions.

Tile and Surface Removal: SDS Plus chisels with a flat or angled blade are suitable for removing tiles, adhesive, mortar, or other surface materials. They can effectively chip away and scrape off unwanted materials from floors, walls, or other surfaces.

Scaling and Cleaning: Some SDS Plus chisels, such as scaling chisels, are specifically designed for scaling and cleaning tasks. They are used to remove scale, rust, paint, or other surface coatings from metal, concrete, or masonry surfaces. The wide cutting edge and flat shape of scaling chisels make them effective in stripping away surface contaminants.

Starting Holes: Pointed SDS Plus chisels are often used for starting holes in hard materials. The sharp tip allows for accurate and controlled drilling, providing a starting point for further drilling or anchoring.

English

English

中文简体

中文简体

Español

Español

عربى

عربى